-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

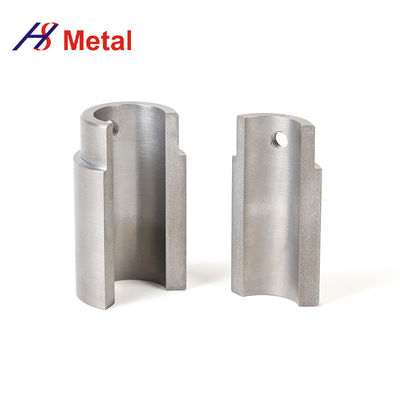

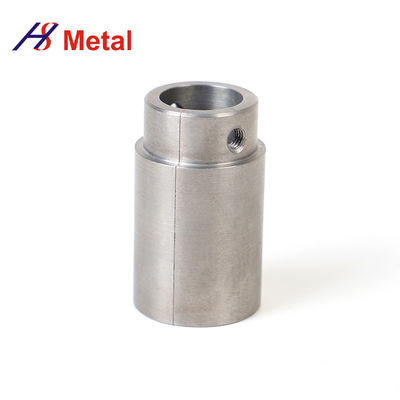

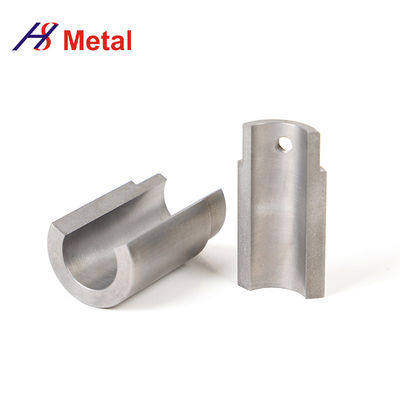

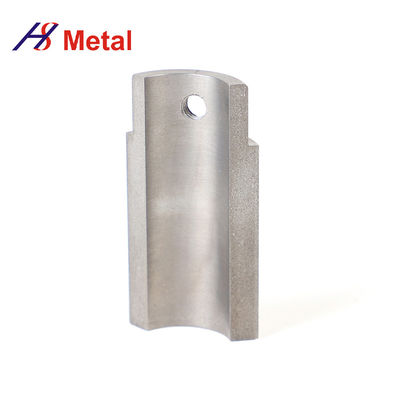

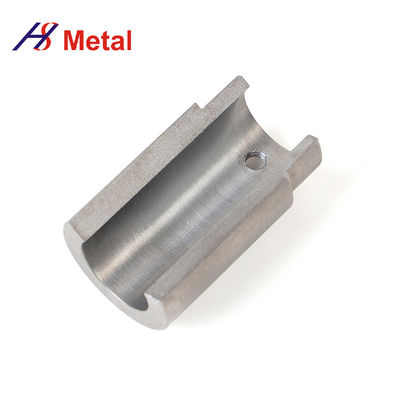

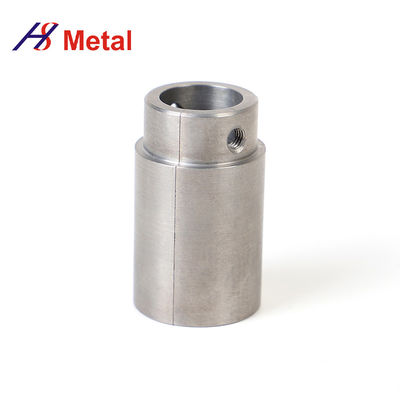

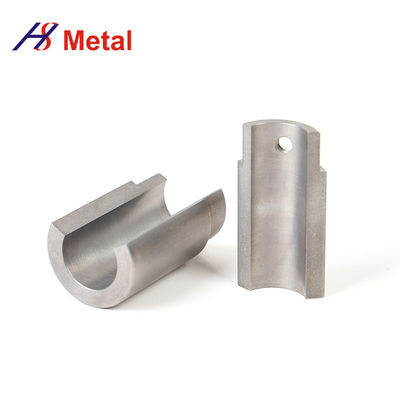

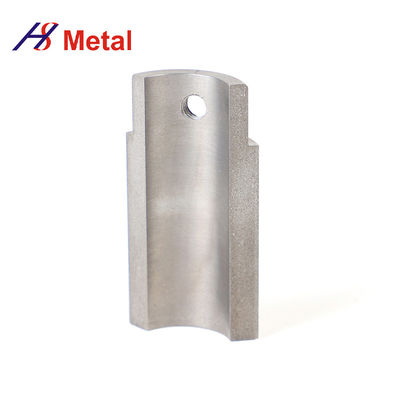

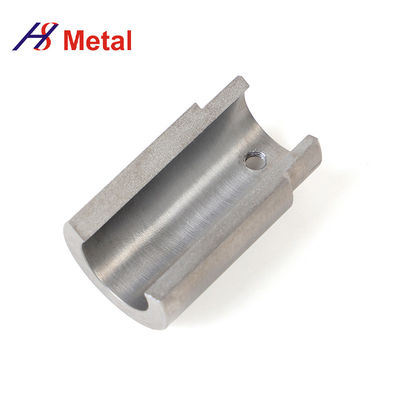

Customized Tungsten Carbide Rollers Various Shape

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Conductivity | Low Thermal And Electrical Conductivity | Density | 19.25 G/cm3 |

|---|---|---|---|

| Electrical Conductivity | 5.5×106 S/m | Surface Roughness | Ra0.4-Ra6.3 |

| Thermal Conductivity | 174 W/m·K | Tolerance | + / - 0.5mm |

| Tungsten Purity | > 99.95% | Welding Current | 60-90,90-120,120-150 |

| Highlight | customized tungsten carbide rollers,various shape tungsten carbide rollers |

||

cemented tungsten carbide rollers tungsten carbide wear parts

1,Description:

Tungsten carbide (WC) is a compound composed of tungsten and carbon. Here is an English description of tungsten carbide:

Tungsten carbide is a hard and dense compound known for its exceptional hardness and wear resistance. It is composed of tungsten (W) and carbon (C) atoms, with a chemical formula of WC. Tungsten carbide is often referred to as a cemented carbide or hardmetal due to its use as a cutting tool material.

Tungsten carbide is renowned for its remarkable hardness, ranking among the hardest materials known, comparable to or even surpassing the hardness of natural diamonds. It exhibits excellent wear resistance, making it highly suitable for applications that require cutting, machining, drilling, and grinding of hard materials such as metals, alloys, and composites.

The exceptional hardness of tungsten carbide is attributed to its crystal structure, which consists of a lattice of tungsten atoms with carbon atoms occupying the interstitial sites. This atomic arrangement results in a rigid and densely packed structure that enables tungsten carbide to withstand high compressive stresses and resist deformation.

2,Specifications:

| Physical Property | Value |

|---|---|

| Melting Point | Approximately 2,870°C |

| Density | 15.63 g/cm³ |

| Hardness (Mohs Scale) | 9.5 - 9.8 |

| Thermal Conductivity | 70 - 120 W/m·K (at room temperature) |

| Coefficient of Thermal Expansion | 4.5 x 10^-6 /°C (in the range of 20-1000°C) |

| Electrical Resistivity | 0.2 - 0.3 µΩ·m (at 20°C) |

| Tensile Strength | 1900 - 2400 MPa |

| Young's Modulus | 550 - 700 GPa |

| Vickers Hardness | 1600 - 2200 HV |

| Fracture Toughness | 7 - 10 MPa·m^0.5 |

![]()