-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

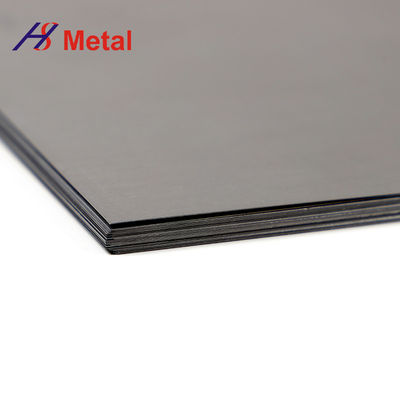

WAL1,WAL2 Tungsten Products Tungsten Steel Plate Good Thermal Conductivity

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

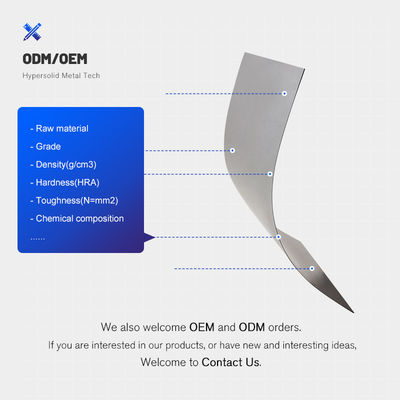

x| Name | Tungsten Plate Supplier | Material | Tungsten |

|---|---|---|---|

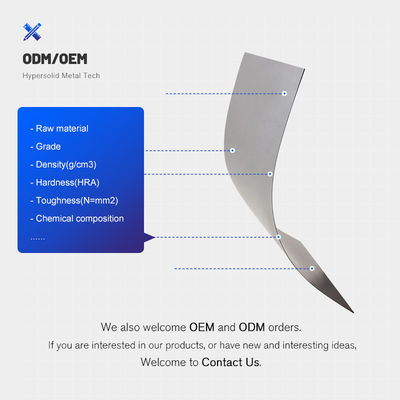

| OEM/ODM | Accepted | Packaging | Carton, Wooden Case, Etc. |

| Payment Term | T/T, L/C, Etc. | Processing Method | CNC Machining, Turning, Milling, Etc. |

| Feature | Good Thermal Conductivity | Surface Treatment | Polishing, Sandblasting, Anodizing, Etc. |

| Tolerance | ±0.01mm | ||

| Highlight | WAL2 Tungsten Products,WAL2 Tungsten Steel Plate,Good Thermal Conductivity Tungsten Steel Plate |

||

WAL1,WAL2 tungsten plate supplier Good thermal conductivity

Features of tungsten plate

* Low coefficient of thermal expansion

* Good thermal conductivity

* High Temperature resistance

* High Intensity

|

Thickness mm |

Width mm |

Length mm |

|

1.0 |

50 |

100 |

|

2.0 |

150 |

200 |

|

3.0 |

350 |

150 |

|

4.0-5.0 |

400 |

400 |

|

5.0-10.0 |

600 |

800 |

|

10.0-15.0 |

800 |

1000 |

|

> 15.0 |

L |

L |

|

Atomic number |

74 |

|

CAS number |

7440-33-7 |

|

Atomic mass |

183.84 [g/mol] |

|

Melting point |

3420 °C |

|

Boiling point |

5555 °C |

|

Density at 20 °C |

19.25 [g/cm3] |

|

Crystal structure |

Body-centered cubic |

|

Coefficient of linear thermal expansion at 20 °C |

4.410-6 [m/(mK)] |

|

Thermal conductivity at 20 °C |

164 [W/(mK)] |

|

Specific heat at 20 °C |

0.13 [J/(gK)] |

|

Electrical conductivity at 20 °C |

18.2106 [S/m] |

|

Specific electrical resistance at 20 °C |

0.055 [(mm2)/m] |

tungsten plate Applications

1. Suitable for producing ion implantation parts;

2.For producing electric light source parts,components of electric vacuum;

3.For producing W-boats,heat shield and heat bodies in high temperature furnace;

4.Used for tungsten sputtering target