-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

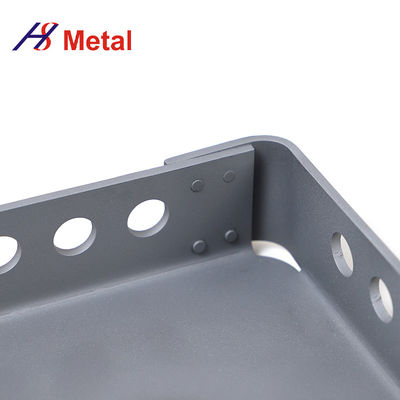

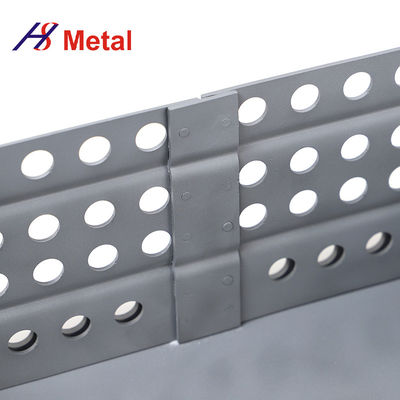

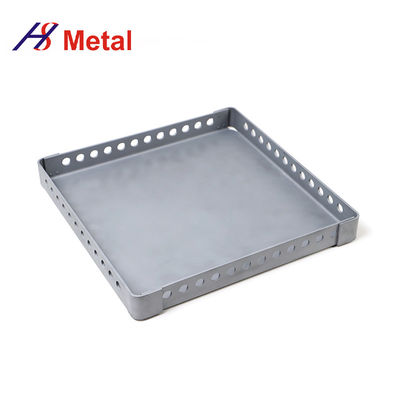

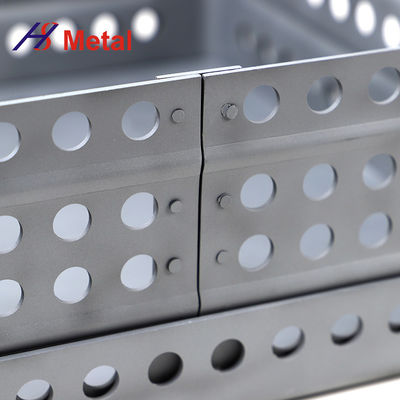

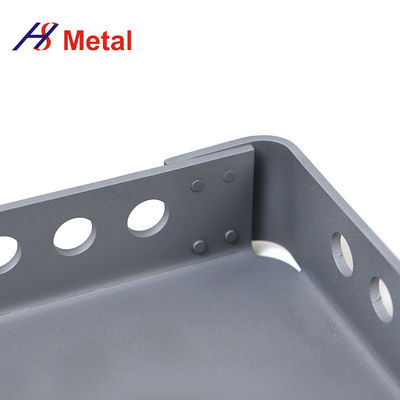

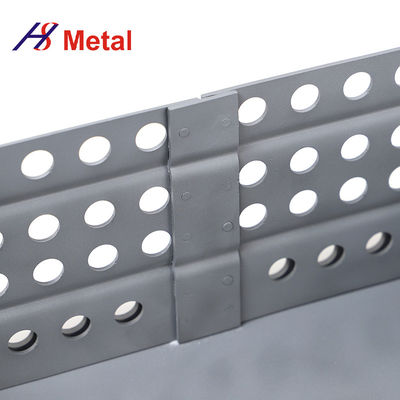

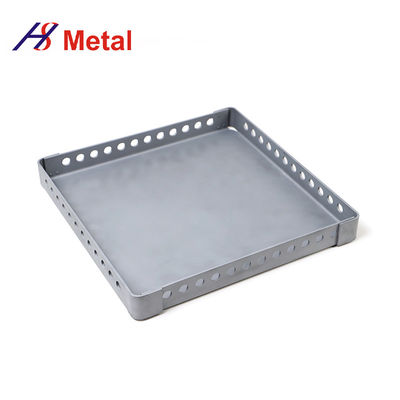

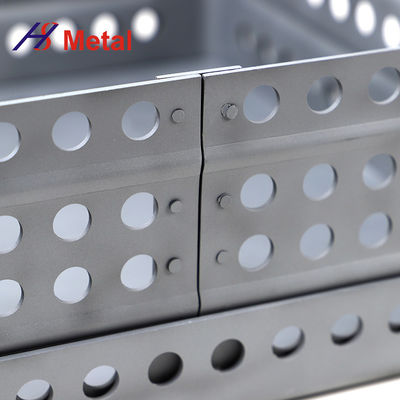

Molybdenum Tray Vacuum Furnace Molybdenum Container Moly Tray Molybdenum Box Industrial Applications

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Operating Temperature | 1400~2000℃ | Mo Content | >=99.95% |

|---|---|---|---|

| Elongation | 10% | Use Temperature | 1400~2000℃ |

| Shape | Boat | Lanthanum Content | 0.3%~0.7% |

| Hardness | 250 HB | Material | Molybdenum |

| High Light | Industrial molybdenum tray,Vacuum furnace molybdenum tray,Container Moly Molybdenum Tray |

||

1,Description:

-

Thermal Conductivity: Molybdenum boats possess good thermal conductivity, allowing for efficient heat transfer and uniform heating of the materials held within them.

-

Corrosion Resistance: Molybdenum boats exhibit excellent resistance to corrosion, making them suitable for use in chemically reactive environments or with corrosive materials.

-

Purity and Density: Molybdenum boats are available in different purity grades, including high-purity molybdenum. They have a high density ranging from 9.8 to 10.2 g/cm³, providing good structural stability and durability.

-

Applications: Molybdenum boats find applications in various industries, including semiconductor, electronics, metallurgy, and research laboratories. They are commonly used for thermal evaporation, sintering, metal injection molding, and as crucibles for melting and casting metals.

-

Machinability: Molybdenum is a challenging material to machine due to its high hardness. Specialized machining techniques and tools are required to shape and fabricate molybdenum boats accurately.

2,Specifications:

| Density | 9.8 - 10.2 g/cm³ |

| Corrosion Resistance | Excellent resistance to corrosion |

| Thermal Conductivity | 138 - 142 W/m·K |

| Purity | Standard or high purity grades |

| Strength | High strength and hardness |

| Machinability | Challenging to machine due to high hardness |

![]()