-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

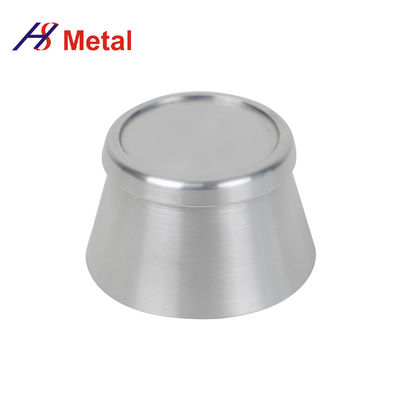

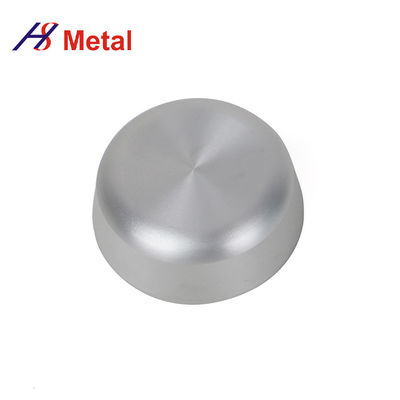

Cheap molybdenum material high purity crucible for Vacuum Evaporation System

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Moly Crucible | Standard | ASTM B386 |

|---|---|---|---|

| Material | >99.95% | Density | 10.20g/cm3 |

| Size | Customized Machined | Feature | High Melting Point |

| Highlight | Molybdenum Crucibles Customized,Polished Molybdenum Crucibles,Polished Tungsten Molybdenum Crucible |

||

![]()

Molybdenum (Mo) crucibles are renowned for their exceptional thermal stability, capable of withstanding temperatures up to an impressive 2610°C. This characteristic makes them indispensable in high-temperature vacuum furnace environments, where precision and durability are paramount. These crucibles are particularly valued in specialized industries that require materials processing at extreme temperatures.

Parameters

| Atomic number | 42 |

| CAS number | 7439-98-7 |

| Atomic mass | 95.94 [g/mol] |

| Melting point | 2620 °C |

| Boiling point | 4639 °C |

| Density at 20 °C | 10.22 [g/cm³] |

| Crystal structure | Body-centered cubic |

| Coefficient of linear thermal expansion at 20 °C | 5.2 × 10-6 [m/(mK)] |

| Thermal conductivity at 20 °C | 142 [W/(mK)] |

| Specific heat at 20 °C | 0.25 [J/(gK)] |

| Electrical conductivity at 20 °C | 17.9 × 106 [S/m] |

| Specific electrical resistance at 20 °C | 0.056 [(Ωmm2)/m] |

Application

-

Sapphire Crystal Growth Furnaces: In the production of synthetic sapphires, Mo crucibles play a crucial role due to their ability to maintain structural integrity under the intense conditions necessary for crystal growth. Sapphire, used in various applications from watch faces to semiconductor wafers, requires temperatures exceeding 1500°C, making Mo crucibles an ideal choice.

-

Quartz Glass Melting Furnaces: Quartz glass manufacturing also benefits from the use of Mo crucibles. The high melting point of quartz demands equipment that can handle temperatures well beyond those achievable by conventional materials. Mo crucibles ensure consistent quality and longevity in these demanding environments.

-

Rare Earth Metal Processing Furnaces: Rare earth metals, critical components in numerous high-tech devices, often require high-temperature processing. Mo crucibles offer the necessary resistance to corrosion and deformation at the elevated temperatures needed for melting and refining these valuable elements.

Conclusion: The Mo sheet's remarkable performance at temperatures above 1500°C is a testament to its suitability for advanced furnace applications. Whether in the creation of high-purity crystals, the manufacturing of specialized glasses, or the processing of rare earth metals, Mo crucibles provide a reliable solution for industries that demand the utmost in thermal stability and material integrity. Their unique properties continue to make them an essential tool in the field of high-temperature materials processing.