-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

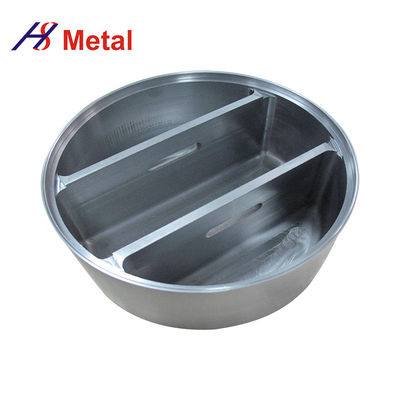

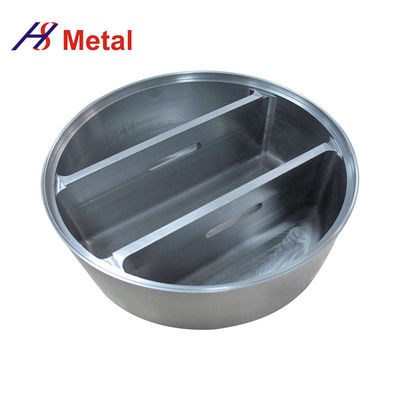

Metal Polished Mo Crucible Pure Molybdenum High Melting Point

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Boiling Point | 5560°C | Feature | High Melting Point |

|---|---|---|---|

| High Temperature | 1700 Degree | Melting Point | 2623°C |

| Size | Customized | Tech | Vacuum Annealing |

| Thermal Expansion Coefficient | 4.8 × 10^-6/K | Yield Strength | ≥275 MPa |

| High Light | high melting point molybdenum crucible,polished mo crucible,high melting point mo crucible |

||

1,Description:

Molybdenum crucibles are containers made from molybdenum, a refractory metal known for its high melting point and excellent thermal and chemical resistance. These crucibles are widely used in various applications, especially in high-temperature environments where other materials would not be able to withstand the extreme conditions.

Molybdenum crucibles exhibit exceptional thermal stability, with a melting point of 2,617°C (4,723°F), which is one of the highest among metals. They have excellent resistance to thermal shock and can endure rapid temperature changes without cracking or deforming. This makes them suitable for use in processes such as melting, sintering, and heat treatment of materials at elevated temperatures.

2,Specifications:

| Density | 10.2 g/cm³ (at 20°C) |

| Melting Point | 2,617°C (4,723°F) |

| Thermal Conductivity | 142 W/m·K (at 20°C) |

| Coefficient of Thermal Expansion | 4.8 x 10^-6 /°C (at 20-1,000°C) |

| Electrical Conductivity | 34% IACS (International Annealed Copper Standard) (at 20°C) |

| Hardness (Mohs) | 5.5 - 6.5 |

| Tensile Strength | 550 - 800 MPa |

| Yield Strength | 350 - 600 MPa |

![]()