-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

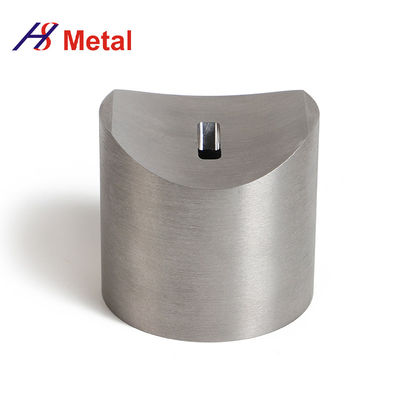

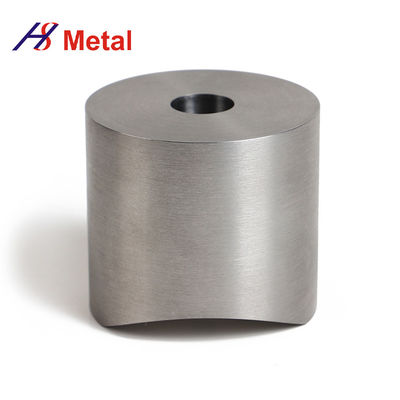

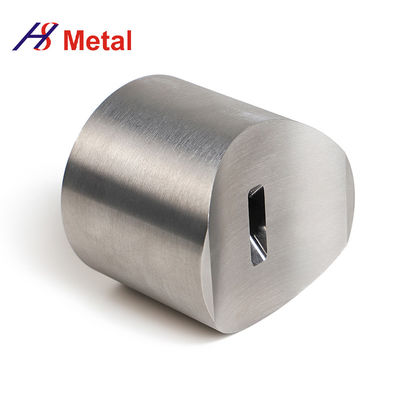

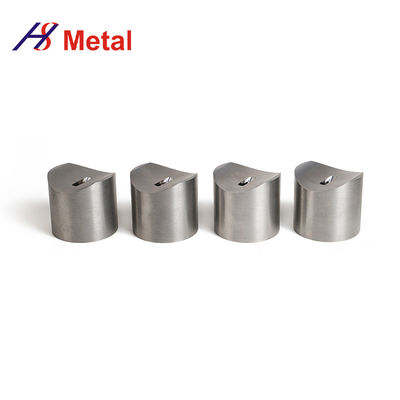

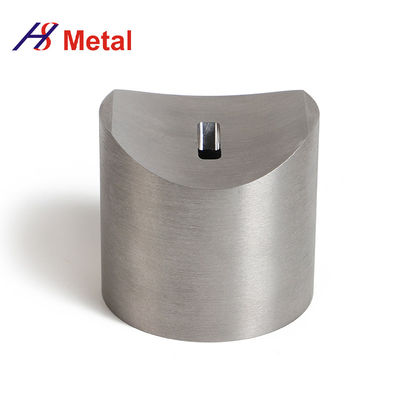

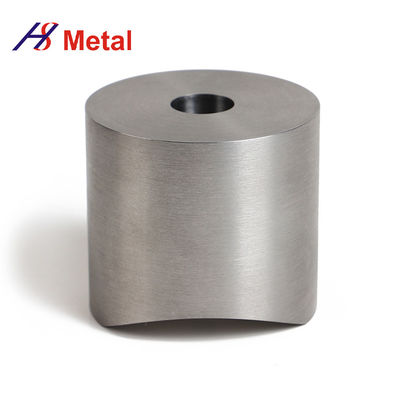

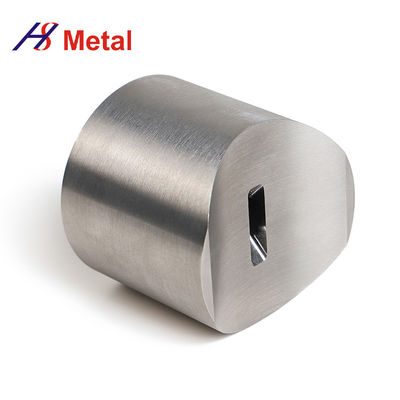

High Purity Silver Grey Wnife Tungsten Heavy Alloy Metal Parts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Diameter | 1.0mm - 100mm | Electronegativity | 2.36 |

|---|---|---|---|

| Hardness | 9.5 Mohs | Heat Conductivity | 0.13 W/mK |

| Inspection | 100% Inspection | Sizes | Customized |

| Supply State | Ground / Polished | Thickness | 0.05mm - 1.0mm |

| High Light | high purity tungsten heavy alloy,wnife tungsten heavy alloy |

||

1,Description:

Tungsten alloys, also known as tungsten heavy alloys (WHAs) or tungsten-based alloys, are composite materials consisting primarily of tungsten with the addition of one or more metallic elements. Here is an English description of tungsten alloys:

Tungsten alloys are dense and high-strength materials that exhibit exceptional mechanical properties. They are composed of tungsten as the primary constituent, typically ranging from 85% to 98% by weight, with the remaining portion consisting of other metals such as nickel (Ni), copper (Cu), iron (Fe), and molybdenum (Mo).

The addition of these metallic elements to tungsten enhances the ductility, machinability, and formability of the alloy, while still maintaining the desirable properties of tungsten, such as high density, high melting point, and excellent thermal and electrical conductivity.

Tungsten alloys are renowned for their high density, often surpassing that of lead and steel. This property makes them ideal for applications requiring weight concentration, such as aerospace components, balance weights, radiation shielding, and kinetic energy penetrators.

2,Specifications:

| Physical Property | Value Range |

|---|---|

| Density | 15.6 - 19.3 g/cm³ |

| Melting Point | 2,870 - 3,420°C |

| Thermal Conductivity | 60 - 120 W/m·K (at room temperature) |

| Coefficient of Thermal Expansion | 4.5 - 6.0 x 10^-6 /°C (in the range of 20-1000°C) |

| Electrical Conductivity | 13 - 33% IACS (International Annealed Copper Standard) |

| Hardness (Rockwell C) | 24 - 35 HRC |

| Tensile Strength | 550 - 1100 MPa |

| Yield Strength | 400 - 900 MPa |

| Elongation at Break | 0.5 - 30% |

![]()