-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

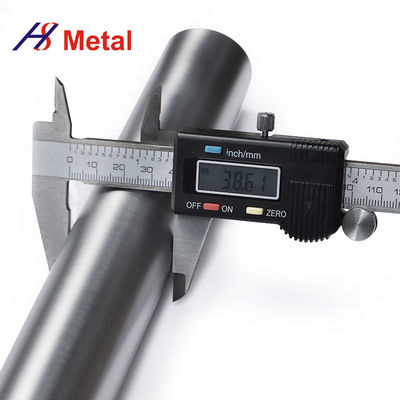

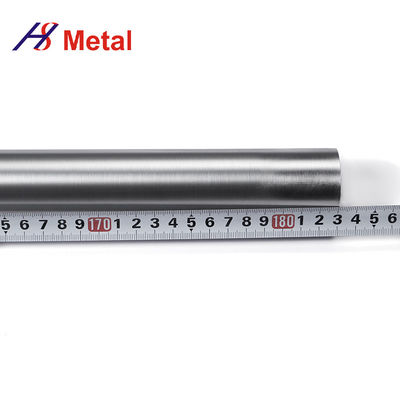

10.2 G/Cm3 Molybdenum Bar Molybdenum Rod High Boiling Point

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Boiling Point | 4639°C | Density | 10.2 G/cm3 |

|---|---|---|---|

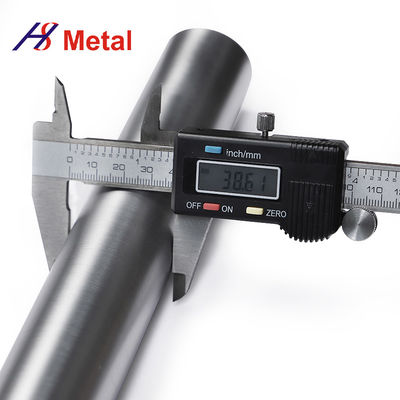

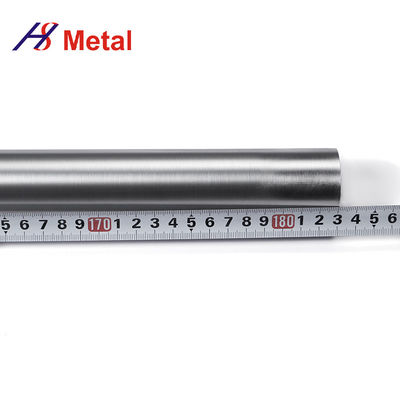

| Dia | 3.18mm - 152mm | Electrical Conductivity | 35% IACS |

| Electrical Resistivity | ≤0.095 μΩ.m | Elongation | 10% |

| Material | Molybdenum | Molybdenum Melting Poin | 2620 °C |

| Highlight | 10.2 g/cm3 molybdenum bar,high Boiling Point molybdenum bar,10.2 g/cm3 molybdenum rod |

||

1,Description:

-

Molybdenum Bars are widely used in various industries, including aerospace, electronics, and high-temperature applications, due to their exceptional thermal and mechanical properties.

-

These bars exhibit a high melting point and excellent thermal conductivity, making them suitable for applications requiring heat resistance and efficient heat transfer.

-

Molybdenum Bars possess remarkable corrosion resistance, allowing them to withstand aggressive chemical environments and harsh operating conditions.

-

With their high density, Molybdenum Bars are often utilized as radiation shields in nuclear applications and as counterweights in various machinery and equipment.

-

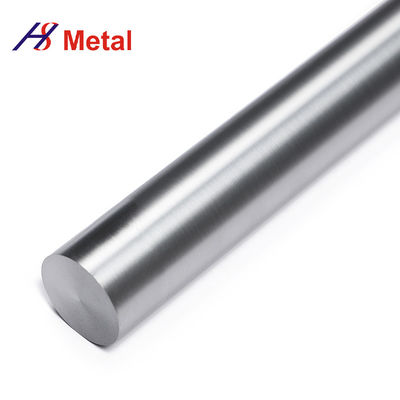

The mechanical properties of Molybdenum Bars, such as high tensile strength and good ductility, make them suitable for use in structural components and load-bearing applications.

-

Molybdenum Bars can be machined, forged, and fabricated into various shapes and sizes to meet specific design requirements and application needs.

2,Specifications:

| Physical Property | Value |

|---|---|

| Melting Point | Approximately 2,620°C |

| Density | 10.2 g/cm³ |

| Thermal Conductivity | 138 W/m·K (at room temperature) |

| Coefficient of Thermal Expansion | 4.8 x 10^-6 /°C (in the range of 20-1000°C) |

| Electrical Conductivity | 31% IACS (International Annealed Copper Standard) |

| Hardness (Rockwell C) | 30 - 35 HRC |

| Tensile Strength | 580 - 820 MPa |

| Yield Strength | 340 - 690 MPa |

| Elongation at Break | 10 - 30% |

![]()