-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

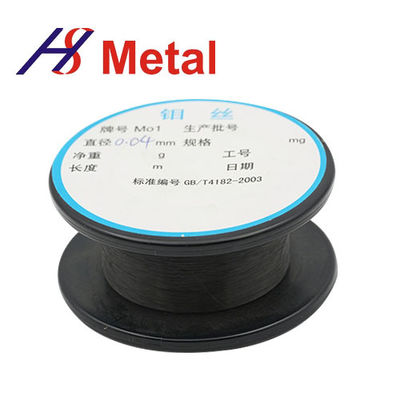

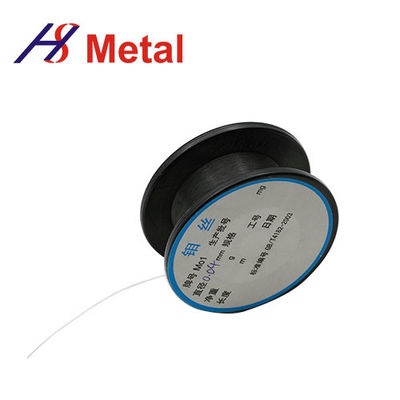

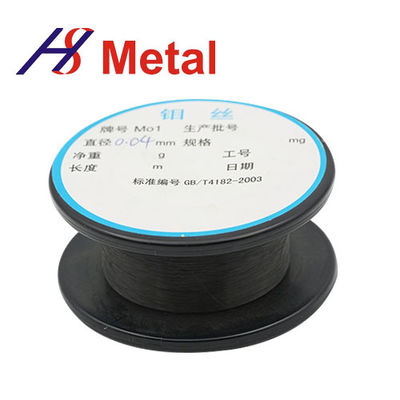

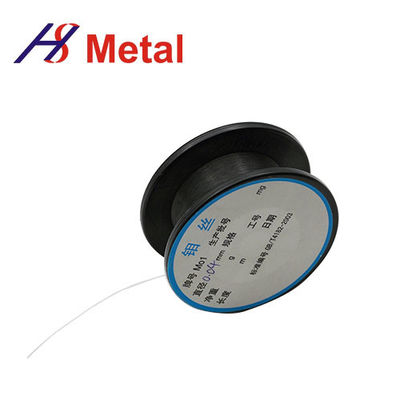

Customized Molybdenum Wire Cut Edm Diameter 0.18 Mm 0.2mm 0.25mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Boiling Point | 5560℃ | Density | 10.2g/cm3 |

|---|---|---|---|

| Diameter | 0.1-10mm | Electrical Resistivity | ≤1.2μΩ.m |

| Elongation | ≥20% | Length | Customized |

| Material | Molybdenum | Shape | Wire |

| Highlight | molybdenum wire cut edm 0.2 mm,Customized molybdenum wire cut edm,cutting edm molybdenum wire 0.18 mm |

||

1,Description:

High Melting Point: Molybdenum has a high melting point of approximately 2,620 degrees Celsius (4,748 degrees Fahrenheit), allowing it to withstand extremely high temperatures.

High Tensile Strength: Molybdenum wire has excellent tensile strength, making it strong and resistant to breaking or stretching under tension.

Good Ductility: Molybdenum wire is highly ductile, allowing it to be easily drawn into thin wires or formed into various shapes without breaking.

2,Specifications:

| Material | High-purity molybdenum |

| Melting Point | Approximately 2,620 degrees Celsius (4,748 degrees Fahrenheit) |

| Tensile Strength | High tensile strength, resistant to breaking or stretching |

| Electrical Conductivity | Excellent electrical conductivity |

| Thermal Conductivity | Relatively good thermal conductivity |

| Coefficient of Thermal Expansion | Low thermal expansion |

| Corrosion Resistance | Good resistance to corrosion and oxidation |

![]()