-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

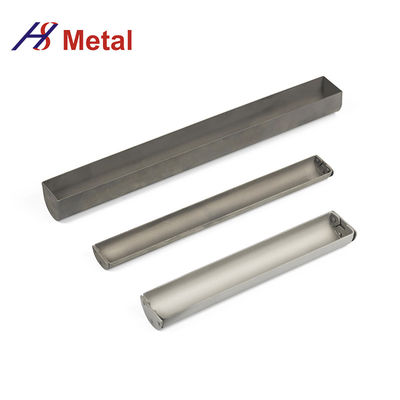

High Density Molybdenum Lanthanum Alloy Mola Mo-La Mo La Rod Bar Plate Sheet

| Place of Origin | China |

|---|---|

| Brand Name | Hypersolid Metal |

| Model Number | Molybdenum Lanthanum Alloy |

| Minimum Order Quantity | Negotiate |

| Price | Negitionable |

| Packaging Details | Standard export cartons |

| Delivery Time | 30 days after receiving down payment |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 10000sets/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Electrical Resistivity | 5-50 µΩ·m | Elongation | 10-30% |

|---|---|---|---|

| Hardness | 200-400 HV | Modulus Of Elasticity | 200-400 GPa |

| Specific Heat Capacity | 0.25-0.35 J/g·K | Tensile Strength | 200-400 MPa |

| Thermal Conductivity | 100-200 W/mK | Thermal Expansion | 4.2-4.6 µm/mK |

| Type | Alloy | Yield Strength | 150-300 MPa |

| Highlight | high density molybdenum lanthanum,molybdenum lanthanum rod,high density molybdenum alloy |

||

Description:

Molybdenum Lanthanum Alloy is a composite material consisting of molybdenum (Mo) and lanthanum (La) elements. Here's an English description of Molybdenum Lanthanum Alloy:

Molybdenum Lanthanum Alloy is a specialized alloy that combines the unique properties of molybdenum and lanthanum to create a high-performance material with enhanced characteristics. This alloy is primarily used in applications requiring high-temperature strength, excellent creep resistance, and improved resistance to oxidation.

Key features and properties of Molybdenum Lanthanum Alloy include:

-

High-Temperature Strength: The addition of lanthanum to molybdenum enhances its high-temperature strength, making it suitable for applications in extreme thermal environments. The alloy maintains its structural integrity and mechanical properties at elevated temperatures, surpassing those of pure molybdenum.

-

Improved Creep Resistance: Molybdenum Lanthanum Alloy exhibits improved resistance to creep deformation under high temperatures and mechanical stress. This property is crucial for applications that involve prolonged exposure to high temperatures, such as in furnace components or aerospace propulsion systems.

-

Enhanced Oxidation Resistance: The presence of lanthanum in the alloy enhances its resistance to oxidation, enabling it to withstand oxidizing atmospheres at elevated temperatures. This makes Molybdenum Lanthanum Alloy suitable for applications in environments that involve exposure to air, steam, or certain gases.

Specifications:

| Chemical Composition | Molybdenum (Mo) and Lanthanum (La) |

| Density | 9.2 - 9.5 g/cm³ |

| Melting Point | Approximately 2,800 degrees Celsius (5,072 degrees Fahrenheit) |

| Thermal Conductivity | 120 - 140 W/m·K |

| Coefficient of Expansion | 5.2 x 10^(-6) K^(-1) |

| Electrical Conductivity | 15 - 20% IACS (International Annealed Copper Standard) |

| Elastic Modulus | 320 GPa |

| Hardness (Mohs) | 5.5 |

| Tensile Strength | 700 - 1,000 MPa |

| Yield Strength | 450 - 800 MPa |

| Elongation at Break | 10 - 20% |

![]()