-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

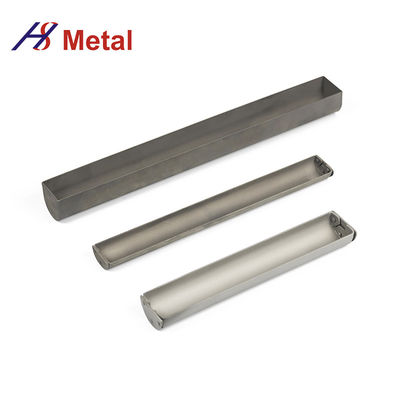

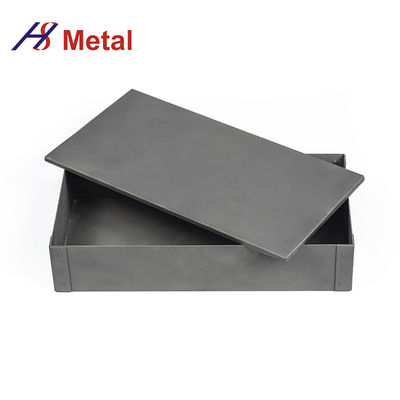

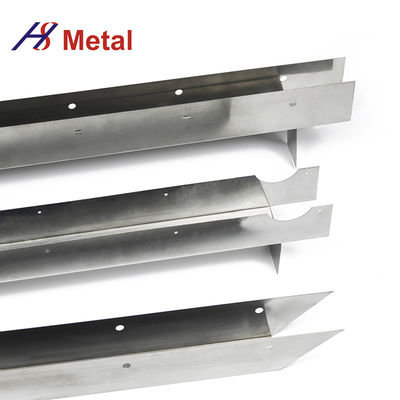

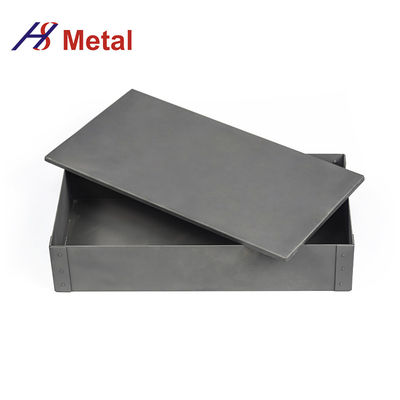

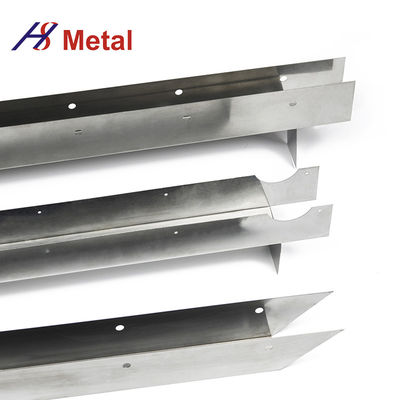

High Purity Customized Molybdenum Lanthanum Alloy Mola Plate Sheet

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Atomic Number | 42 | Content | Mo-La Alloy |

|---|---|---|---|

| Density | 10.2 G/cm3 | Melt Point | 2617 |

| Package | Wooden Case | Purity | Over 99.97% |

| Size | Customized | Temper | 1000-1800℃ |

| Highlight | molybdenum lanthanum alloy high purity,molybdenum lanthanum alloy customized |

||

1,Description:

Molybdenum-lanthanum alloys, also known as Mo-La alloys, are composite materials that contain molybdenum as the primary constituent with the addition of a small percentage of lanthanum. Here is an English description of Mo-La alloys:

Mo-La alloys are characterized by their excellent high-temperature strength, remarkable creep resistance, and improved ductility compared to pure molybdenum. The addition of lanthanum, a rare-earth element, enhances the mechanical properties and performance of molybdenum in various applications.

Mo-La alloys exhibit higher recrystallization temperatures, making them suitable for use in elevated temperature environments. They maintain their mechanical properties at temperatures up to 1,900°C (3,450°F), making them ideal for applications requiring excellent thermal stability and resistance to deformation, such as high-temperature furnace components and aerospace engine parts.

The addition of lanthanum to molybdenum refines the grain structure and improves the ductility of the alloy, allowing for easier forming and shaping processes. Mo-La alloys can be readily machined, rolled, forged, or drawn into different shapes and sizes, offering versatility in manufacturing and design.

2,Specifications:

|

|---|

![]()