-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

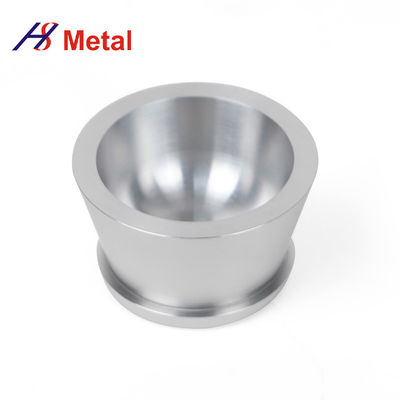

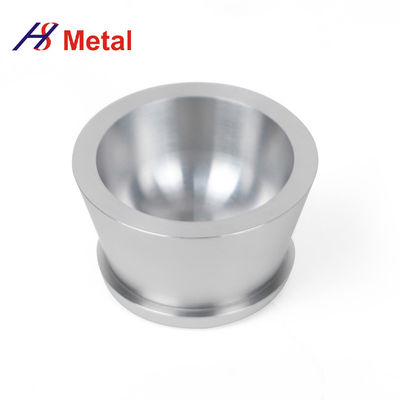

Forging Sintering Tungsten Melting Crucible Low Thermal Expansion Smooth

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Corrosion Resistance | Good | Material | Tungsten |

|---|---|---|---|

| Processing Method | Casting | Resistance | High |

| Shape | Crucible | Surface | Smooth |

| Size | Customized | Thermal Expansion | Low |

| Thickness | Customized | Weight | Customized |

| Highlight | Sintering Tungsten Crucible,Low Thermal Expansion Tungsten Crucible,Forging Tungsten Melting Crucible |

||

Forging / Sintering Tungsten Crucible 0.5 - 100 Litres

Tungsten Crucible Feature

1. According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming, and welding forming.

2. Turning to form is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3. We can produce a tungsten crucible for vacuum coating according to the customer's drawing.

Specification

| delivery condition | specification | tolearance | thickness | roughness | ||

| diameter | height | diameter | height | |||

| sintered | 10-550 | 10-750 | +/-5.0 | +/-5.0 | 8-20 | <3.5 |

| sintering finishing | 10-450 | 10-550 | +/-0.5 | +/-1.0 | 7-18 | <2.5 |

| Atomic number | 74 |

| CAS number | 7440-33-7 |

| Atomic mass | 183.84 [g/mol] |

| Melting point | 3420 °C |

| Boiling point | 5555 °C |

| Density at 20 °C | 19.25 [g/cm3] |

| Crystal structure | Body-centered cubic |

| Coefficient of linear thermal expansion at 20 °C | 4.410-6[m/(mK)] |

| Thermal conductivity at 20 °C | 164 [W/(mK)] |

| Specific heat at 20 °C | 0.13 [J/(gK)] |

| Electrical conductivity at 20 °C | 18.2106[S/m] |

| Specific electrical resistance at 20 °C | 0.055 [(mm2)/m] |

Tungsten Crucible Application

- Used for sapphire single crystal growth furnace

- Applied for quartz glass melting furnace;

- Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.