-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

Tungsten Copper Alloy Materials Electronic Packaging Base Flanges

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

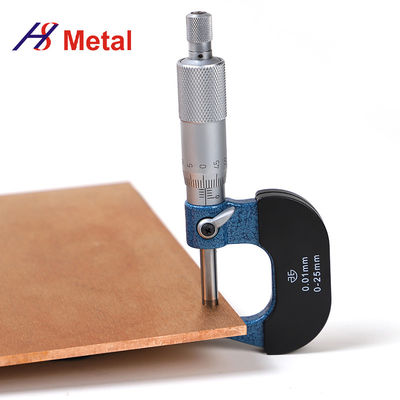

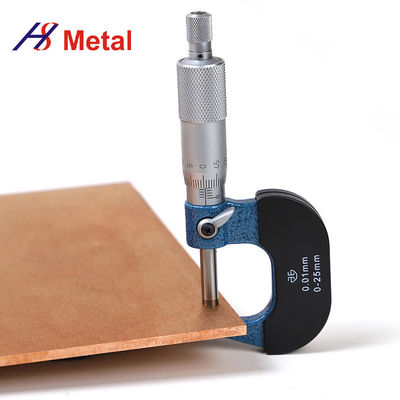

x| Density | 14.5 G/cm3 | Thermalconductivity | 90 W/m·K |

|---|---|---|---|

| Shape | Plate And Sheet | Hardness | 250-300 HB |

| Cobalt Content | 6-8% | Impact Toughness | ≥2.5J/cm2 |

| Material | Tungsten And Copper | Original | China |

![]()

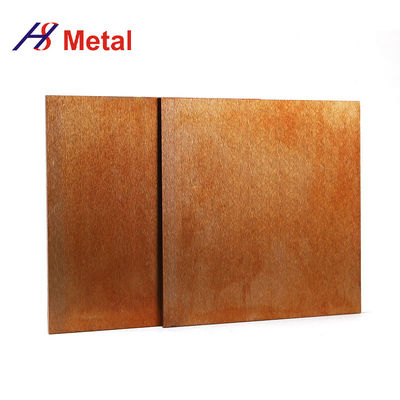

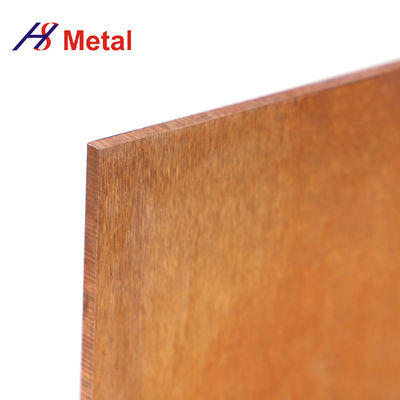

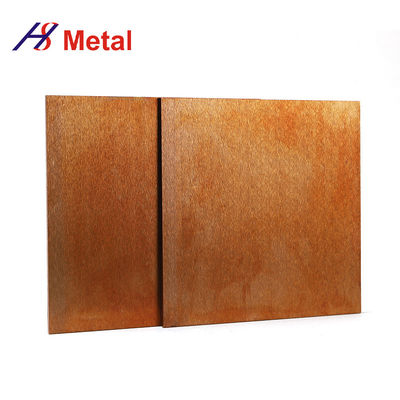

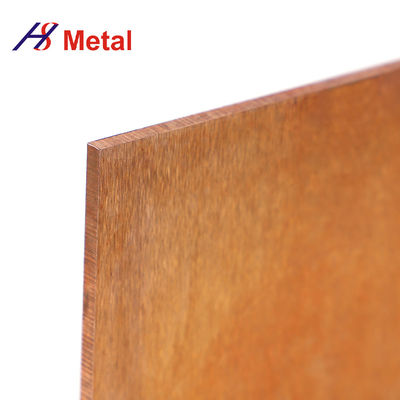

Tungsten Copper Alloy Sheets: A Fusion of Strength and Conductivity

Innovative engineering solutions often demand materials that can perform under the most challenging conditions. Tungsten Copper Alloy sheets offer a compelling blend of tungsten's robust characteristics with copper's superior conductive abilities, making them indispensable across a wide range of industries.

These sheets harness the power of tungsten, known for its unparalleled density and extraordinary strength. With one of the highest melting points in the metallic world, tungsten ensures that the alloy can resist deformation even in the face of extreme temperatures. This makes the alloy particularly suitable for environments where thermal stability is critical, such as in advanced aerospace components and high-performance electronics.

2,Specifications:

| Physical Property | Description |

|---|---|

| Composition | Tungsten (W) and Copper (Cu) |

| Density | Typically ranges from 13.5 to 16.5 g/cm³ |

| Melting Point | Approximately 3400°C (6150°F) for pure tungsten |

| Thermal Conductivity | Ranges from 180 to 230 W/(m·K) |

| Electrical Conductivity | Ranges from 20 to 60% IACS (International Annealed Copper Standard) |

| Hardness | Typically ranges from 200 to 300 HB (Brinell Hardness) |

![]()