-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

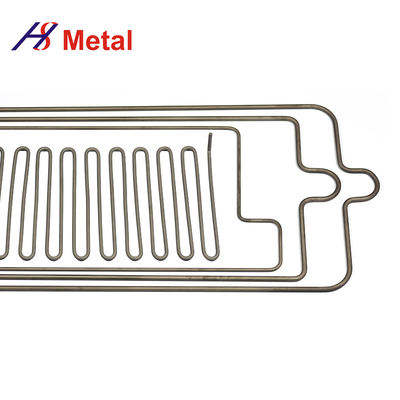

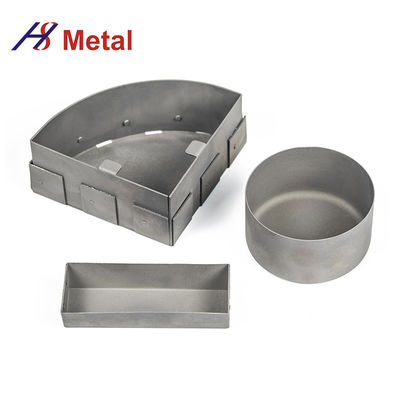

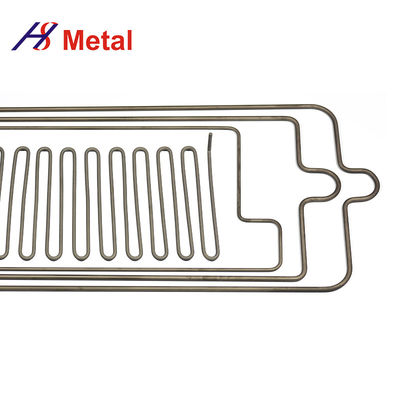

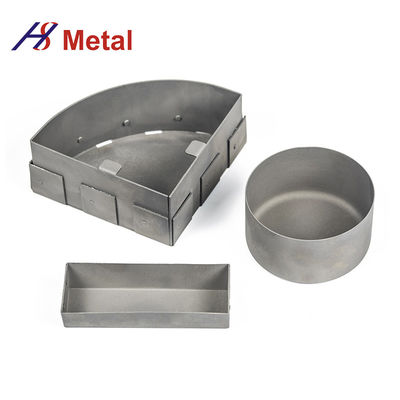

Tungsten Heating Vacuum Coating Tungsten Filament Wire Tungsten Wire Heater Baskets For Vacuum Coating

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | tungsten heating vacuum coating,tungsten evaporation coating,tungsten thermal evaporation |

||

|---|---|---|---|

1,Description:

Tungsten heating vacuum coating, also known as tungsten evaporation coating or tungsten thermal evaporation, is a process used in vacuum deposition to create thin films or coatings of tungsten on various substrates. Here is an English description of tungsten heating vacuum coating:

Tungsten heating vacuum coating is a technique used to deposit thin films or coatings of tungsten onto a substrate surface in a vacuum environment. The process involves the controlled evaporation of tungsten using high temperatures, typically achieved through resistive heating.

In this method, a tungsten filament is heated to its vaporization temperature within a vacuum chamber. As the filament reaches its high temperature, tungsten atoms are released and form a vapor. These tungsten vapor atoms then condense onto the substrate, resulting in the deposition of a thin tungsten film.

2,Specifications:

| Physical Property | Value |

|---|---|

| Density | 19.3 g/cm³ (tungsten) |

| Melting Point | 3,422°C (tungsten) |

| Thermal Conductivity | 173 W/m·K (tungsten) |

| Coefficient of Thermal Expansion | 4.5 x 10^-6 /°C (tungsten) |

| Electrical Conductivity | 31% IACS (International Annealed Copper Standard) (tungsten) |

| Hardness (Vickers) | 343 HV (tungsten) |

![]()