All Products

-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

Contact Person :

sabrina.chen

Phone Number :

+86 15836043611

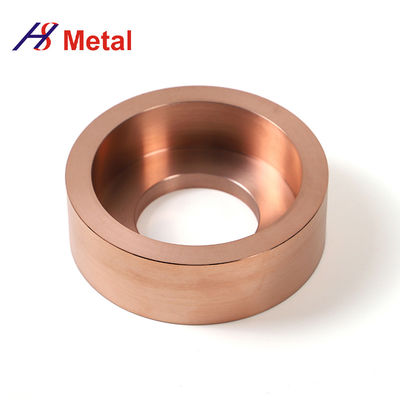

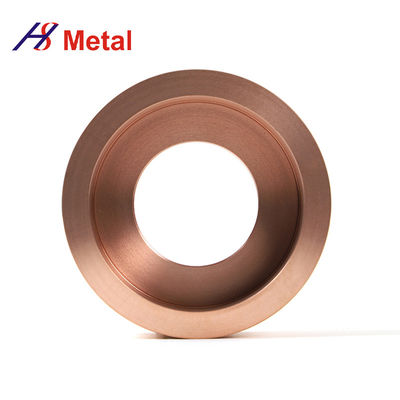

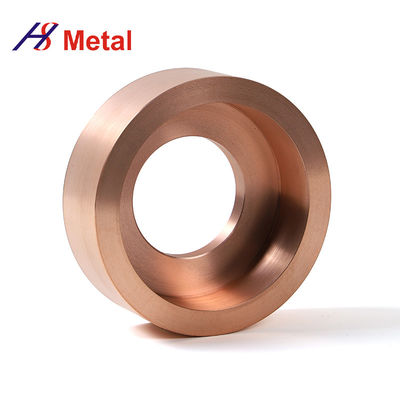

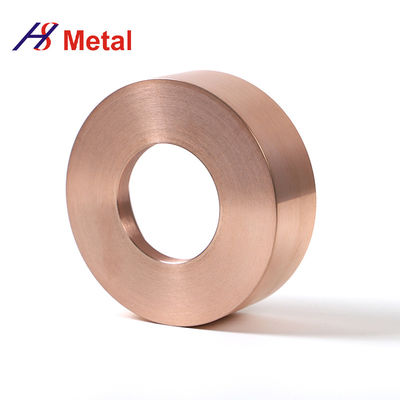

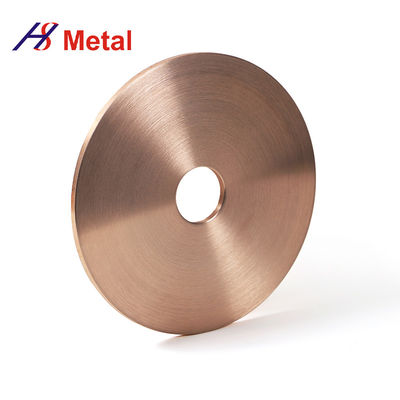

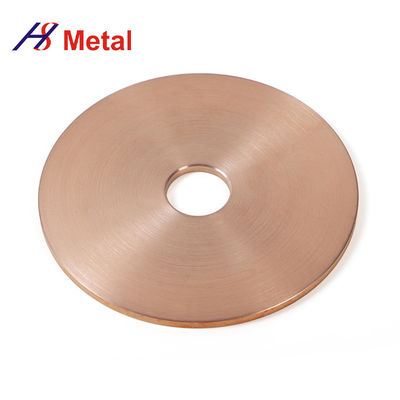

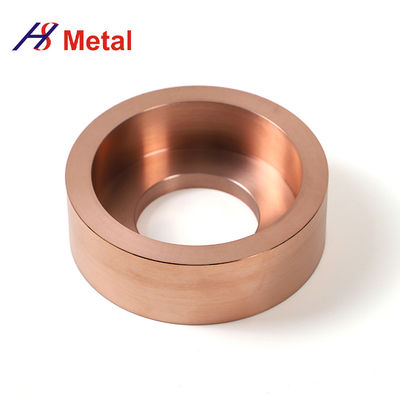

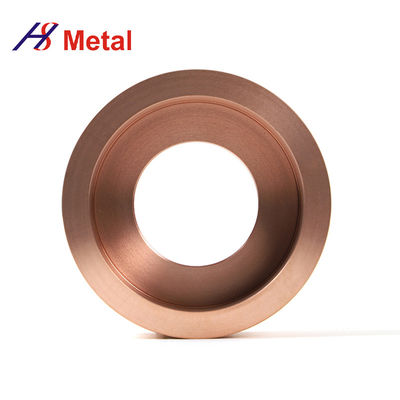

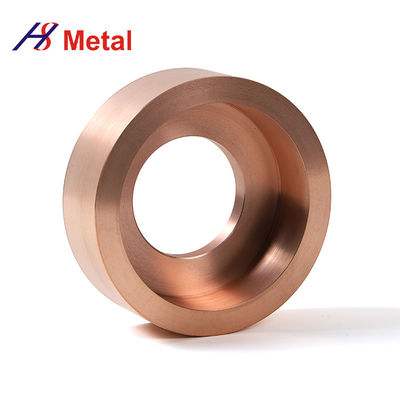

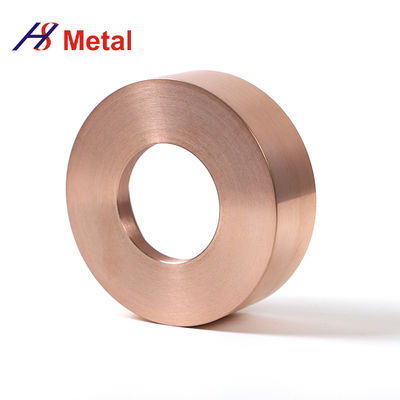

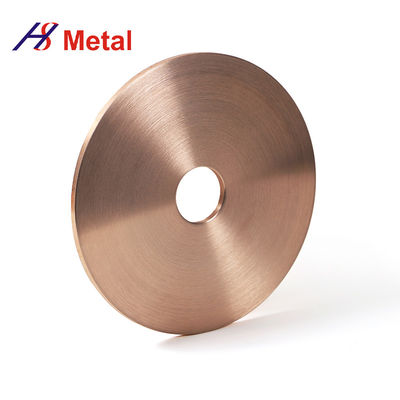

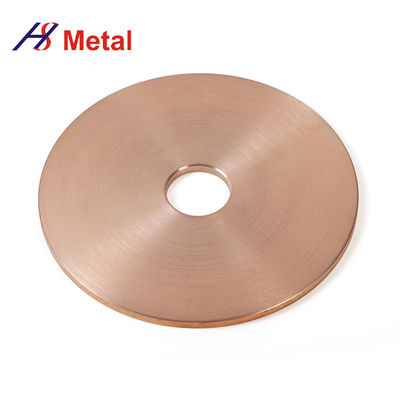

Professional Cuw70 Polished Tungsten Copper Alloy Disc

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Chemical Composition | W75 Cu25 | Cobalt Content | 6-8% |

|---|---|---|---|

| Density | 14.5 G/cm3 | Electrical Conductivity | 25-35% IACS |

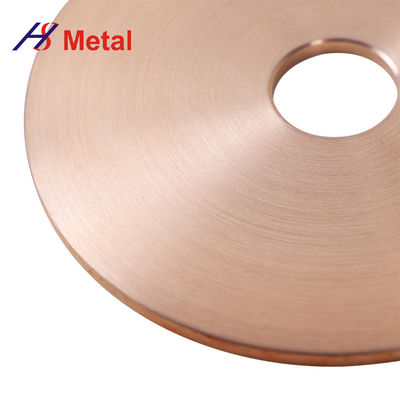

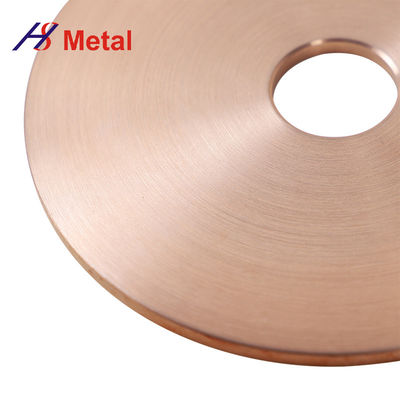

| Meltingpoint | 1495℃ | Surface | Polished |

| Thermalconductivity | 90 W/m·K | Yield Strength | >1000MPa |

| High Light | professional tungsten copper alloy,cuw70 tungsten copper alloy,polished tungsten copper alloy |

||

Product Description

1,Description:

-

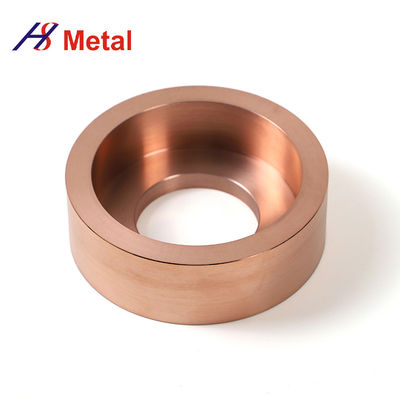

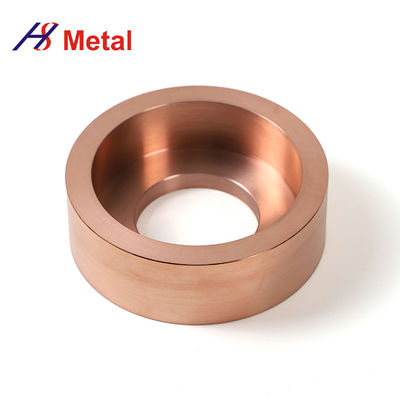

Tungsten Copper Alloy Disc:

A tungsten copper alloy disc is a round-shaped product made by combining tungsten and copper in varying proportions. - Tungsten copper alloy discs are widely used in applications where high thermal conductivity, electrical conductivity, and excellent wear resistance are required.

-

Composition:

Tungsten copper alloy discs typically consist of tungsten content ranging from 50% to 90%, with the remaining portion being copper. - The specific composition can be tailored to meet the requirements of different applications, balancing the desired properties and cost considerations.

-

High Thermal and Electrical Conductivity:

Tungsten copper alloy discs exhibit excellent thermal and electrical conductivity due to the presence of copper. - This combination of properties makes them suitable for applications where efficient heat dissipation or high electrical conductivity is required, such as heat sinks, electrical contacts, and electrode materials.

2,Specifications:

| Property | Value (Unit) |

|---|---|

| Composition | Typically 50-90% Tungsten, 10-50% Copper |

| Density | 14.0-16.5 g/cm³ |

| Melting Point | 3,000-3,400 degrees Celsius |

| Electrical Conductivity | 20-45% IACS |

| Thermal Conductivity | 180-230 W/m·K |

| Coefficient of Thermal Expansion | 6.5-9.0 x 10^-6 per degree Celsius |

| Young's Modulus | 250-320 GPa |

| Hardness (Vickers) | 200-300 HV |

| Tensile Strength | 600-900 MPa |

| Elongation at Break | 3-15% |

![]()

Recommended Products