-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

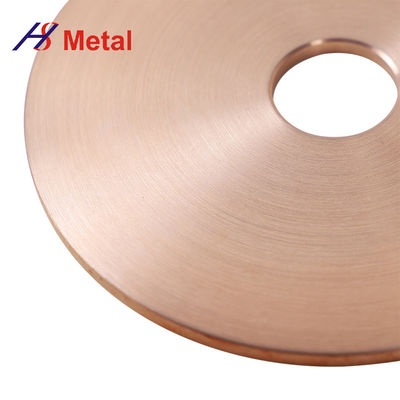

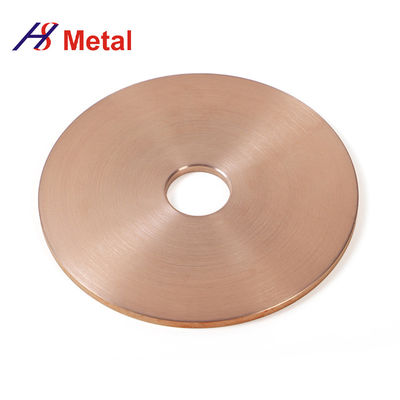

High Hardness Tungsten Copper Alloy Disc Refractory Metal

| Place of Origin | China |

|---|---|

| Brand Name | Hypersolid Metal |

| Model Number | tungsten copper alloy disc |

| Minimum Order Quantity | Negotiate |

| Price | Negitionable |

| Packaging Details | Standard export cartons |

| Delivery Time | 30 days after receiving down payment |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 10000sets/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Coefficient Of Friction | ≤0.3 | Compressive Strength | ≥2500MPa |

|---|---|---|---|

| Density | 17.0-18.5 G/cm³ | Hardness | ≥HRA90 |

| Impact Toughness | ≥15J/cm² | Material | Tungsten Alloy |

| Resistivity | ≤0.2μΩ·m | Yield Strength | ≥1200MPa |

| Highlight | high hardness tungsten copper alloy,refractory tungsten copper alloy |

||

Description:

Tungsten-copper alloy rods, also known as tungsten-copper round bars, are cylindrical components made from a combination of tungsten and copper. This alloy exhibits unique properties that make it suitable for various applications. Here are some descriptions of tungsten-copper alloy rods:

-

High thermal conductivity: Tungsten-copper alloy rods possess excellent thermal conductivity due to the high thermal conductivity of copper. This property allows for efficient heat transfer and dissipation, making them ideal for applications that require effective thermal management, such as in heat sinks and electrical components.

-

High density: The addition of tungsten, a dense material, to the copper matrix increases the density of the alloy. Tungsten-copper alloy rods have a high density, making them useful in applications that require weight concentration, such as in radiation shielding, aerospace components, and high-performance counterweights.

-

Low thermal expansion: Tungsten-copper alloy rods exhibit a low coefficient of thermal expansion, which means they have minimal dimensional changes with temperature fluctuations. This property contributes to their stability and reliability in applications where thermal expansion or contraction could cause issues.

Specifications:

| Alloy Composition | Tungsten (W) and Copper (Cu) |

| Density | 14.5 - 16.0 g/cm³ |

| Thermal Conductivity | 180 - 230 W/m·K |

| Coefficient of Thermal Expansion | 6.5 - 9.0 x 10^(-6) K^(-1) |

| Electrical Conductivity | 30 - 70% IACS (International Annealed Copper Standard) |

| Melting Point | 1,450 - 1,530 degrees Celsius (2,642 - 2,786 degrees Fahrenheit) |

| Young's Modulus | 200 - 350 GPa |

| Tensile Strength | 600 - 1,000 MPa |

| Hardness (Rockwell C) | 20 - 30 HRC |

![]()