-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

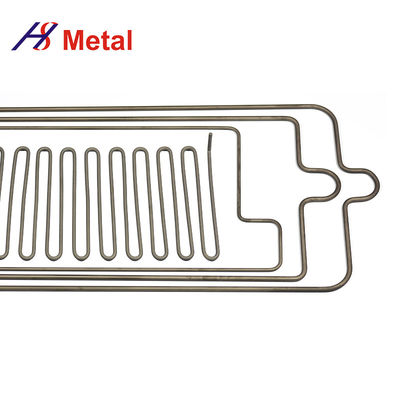

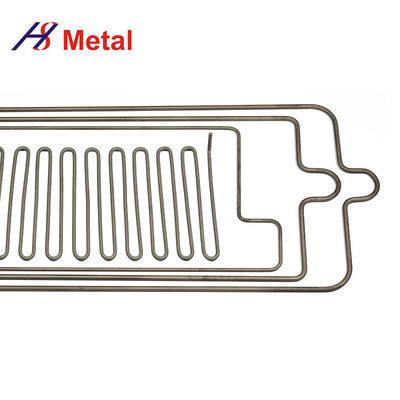

Grey Tungsten Alloy Products High Temperature Furnace Molybdenum Parts Rack

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Molybdenum Parts Rack | Material | 99.95% Pure Molybdenum |

|---|---|---|---|

| Purity | 99.95% | Standard | ASTM B387 |

| Surface | Grey/ Polishing | Feature | High Electrical Conductivity |

| High Light | Grey Tungsten Alloy Products,Grey High Temperature Furnace,Molybdenum Parts Rack |

||

Tungsten Alloy Products High Temperature Furnace Molybdenum Parts Rack

Quick Details

Material: 99.95% Pure Molybdenum

Purity: 99.95%

Density: 10.2g/m³

Size: customized

Standard: ASTM B387

Surface: Grey/ polishing

Melting Point: 2610℃

Boiling Point: 5560℃

High electrical conductivity

High thermal conductivity

High-temperature strength and creep resistance

High dimensional stability

Low coefficient of thermal expansion

Excellent corrosion resistance

Advantages

- Flexible size

- Accurate temperature control

- Friendly environment

- Energy saving

- Easy to operate high temperature working environment

Introduction

The molybdenum material rack, TZM parts racks are used for placing and transferring workpieces needing to be processed in high-temperature annealing furnaces and sintering furnaces, continuous furnace as its High-density, high-temperature strength ,accurate measurement, smooth surface, convenient assembly, and reasonable design of heat components elements for manufacturing racks. we can produce various kinds of parts pure molybdenum, pure tungsten, and molybdenum-lanthanum alloy racks.

Customized Furnace Heat Chamber Parts Molybdenum Heater Parameters

| Sheet/ plate | Bars | Deep processing of products |

| MoLa Alloy plate | Molybdenum and lanthanum alloy bar | Molybdenum-Lanthanum alloy boat, rack |

| Molybdenum and Lanthanum Alloy sheet | Molybdenum Lanthanum alloy rod | Molybdenum-Lanthanum alloy heater, heat shield |

| Molybdenum and Lanthanum Alloy Foil | Molybdenum and lanthanum alloy wire | Molybdenum-lanthanum alloy parts |

| Atomic number | 42 |

| CAS number | 7439-98-7 |

| Atomic mass | 95.94 [g/mol] |

| Melting point | 2620 °C |

| Boiling point | 4639 °C |

| Density at 20 °C | 10.22 [g/cm³] |

| Crystal structure | Body-centered cubic |

| Coefficient of linear thermal expansion at 20 °C | 5.2 × 10-6 [m/(mK)] |

| Thermal conductivity at 20 °C | 142 [W/(mK)] |

| Specific heat at 20 °C | 0.25 [J/(gK)] |

| Electrical conductivity at 20 °C | 17.9 × 106 [S/m] |

| Specific electrical resistance at 20 °C | 0.056 [(Ωmm2)/m] |

Application

The Tungsten and molybdenum products can be widely used to the following industrial through deep processing:

- Furnace support frames, loaded boats in the sapphire crystal furnace and vacuum furnaces.

- Material racks are made of Molybdenum, Tungsten, TZM and its alloy materials, which is widely used in high temperature furnace, vacuum furnace of ceramic, metallurgy, electronics, glass, refractory materials industries.