-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

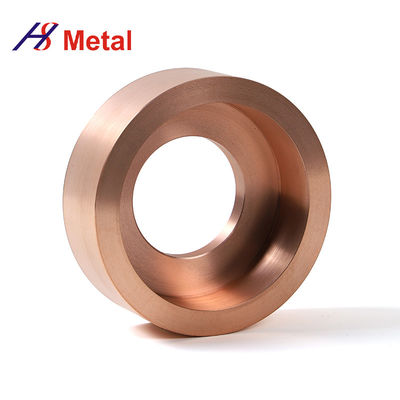

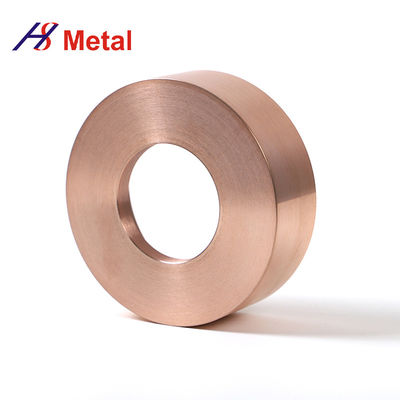

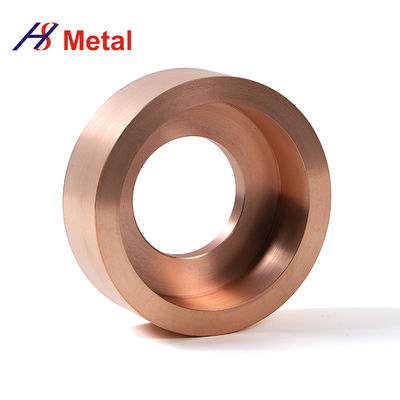

High Intensity Tungsten Copper Ring 80 20 For ECM Electrodes

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Tungsten Copper 80 20 Dics & Ring | Material | Tungsten Copper Alloy |

|---|---|---|---|

| Shape | 11.85-16.75g/cm3 | Application | Electrical |

| Grade | Tungsten Copper 80 20 | Usage | EDM&ECM Electrodes, Electronics, Metallurgy, Machinery |

| Highlight | Tungsten Copper 80 20,Tungsten Copper Ring 80 20,ECM Electrodes Tungsten Copper Ring |

||

High Intensity Tungsten Copper 80 20 Dics & Ring

Usage:

1. EDM (Electrical Discharge Machining) electrodes;

2. ECM (Electrochemical Machining) electrodes;

3. Machining other parts, toys, and so on;

4. Industries such as engine, electric power, electron, metallurgy, spaceflight, and aviation.

Parameters

|

Class |

Chemical Composition (wt%) |

Density |

Hardness |

Resistivity |

IACS |

Bending Strength |

||

|

Cu |

Total Impurities≤ |

W |

g/cm3 ≥ |

HB Kgf/mm2 ≥ |

μΩ.cm ≤ |

% ≥ |

MPa ≥ |

|

|

W50/Cu50 |

50±2.0 |

0.5 |

Balance |

11.85 |

115 |

3.2 |

54 |

— |

|

W55/Cu45 |

45±2.0 |

0.5 |

Balance |

12.3 |

125 |

3.5 |

49 |

— |

|

W60/Cu40 |

40±2.0 |

0.5 |

Balance |

12.75 |

140 |

3.7 |

47 |

— |

|

W65/Cu35 |

35±2.0 |

0.5 |

Balance |

13.3 |

155 |

3.9 |

44 |

— |

|

W70/Cu30 |

30±2.0 |

0.5 |

Balance |

13.8 |

175 |

4.1 |

42 |

790 |

|

W75/Cu25 |

25±2.0 |

0.5 |

Balance |

14.5 |

195 |

4.5 |

38 |

885 |

|

W80/Cu20 |

20±2.0 |

0.5 |

Balance |

15.15 |

220 |

5 |

34 |

980 |

|

W85/Cu15 |

15±2.0 |

0.5 |

Balance |

15.9 |

240 |

5.7 |

30 |

1080 |

|

W90/Cu10 |

10±2.0 |

0.5 |

Balance |

16.75 |

260 |

6.5 |

||

Features

Tungsten-copper alloy has a wide range of applications, most of which are used in aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment, and other industries. Secondly, it is also used to manufacture the contacts of high-voltage electrical switches and high-temperature components such as rocket nozzle throat liner and tail rudder, which are resistant to arc erosion, and also used as electrodes for electrical machining, high-temperature molds and other occasions requiring conductive and thermal conductivity and high-temperature use.