All Products

-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

Contact Person :

sabrina.chen

Phone Number :

+86 15836043611

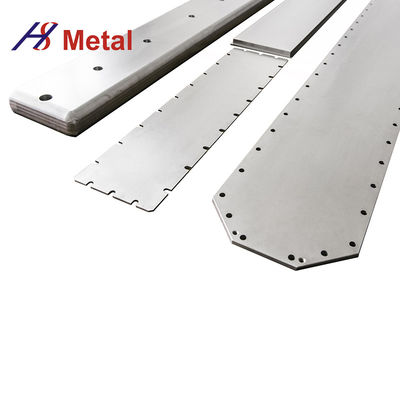

95W3Ni2Fe 97W2Ni1Fe Tungsten Heavy Alloy Nickel Sintering Heat Treatment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Name | Nickel Tungsten Alloy | Composition | 95W3Ni2Fe 97W2Ni1Fe |

|---|---|---|---|

| Standard | ASTM B 777 | Grade | Class 1 Class 2 Class 3 Class 4 |

| Heat Treatment | Sintering | Type | Tungsten Heavy Metal |

| Highlight | Sintering Tungsten Heavy Alloy,Nickel Tungsten Heavy Alloy,Sintering Nickel Tungsten Alloy |

||

Product Description

95W3Ni2Fe 97W2Ni1Fe Tungsten Heavy Metal Nickel Tungsten Alloy

Feature

* High radiation adsorption capability;

* High impact resistance and crack resistance;

* High ultimate tensile strength;

* High temperature resistance;

* Deep Processing property significantly increased;

* Weldability and oxidation resistance greatly enhanced;

* Yield increase and cost reduction;

* A certain Magnetic;

* High ultimate tensile strength;

* High temperature resistance;

* Deep Processing property significantly increased;

* Weldability and oxidation resistance greatly enhanced;

* Yield increase and cost reduction;

* A certain Magnetic;

Parameters

|

AMS-T-21014

|

Class 1

|

Class 2

|

Class 3

|

Class 4

|

|

Composition

|

90W7Ni3Fe

|

92W5Ni3Fe

|

95W3Ni2Fe

|

97W2Ni1Fe

|

|

Density (g/cm3)

|

17.1±0.15

|

17.50±0.15

|

18.10±0.15

|

18.50±0.15

|

|

Heat Treatment

|

Sintering

|

Sintering

|

Sintering

|

Sintering

|

|

Tensile Strength (Mpa)

|

900-1000

|

900-1000

|

920-1100

|

920-1100

|

|

Elongation (%)

|

18-29

|

16-26

|

10-22

|

6-13

|

|

Hardness (HRC)

|

24-28

|

25-29

|

27-32

|

28-36

|

|

Mil-T-21014

|

Class1

|

Class2

|

|

Composition

|

90%W,

6%Ni4%Cu |

95%W,

3.5%Ni 1.5% Cu |

|

Density (gm/cc; lbs/in3)

|

17;0.614

|

18;0.65

|

|

Hardness (RC)

|

24

|

27

|

|

Ultimate Tensile Strength (PSI)

|

110,000

|

110,000

|

|

Yield Strength, 2% Offset (PSI)

|

80,000

|

85,000

|

|

Elongation (% In 1“)

|

6

|

7

|

|

Proportional Elastic Limit (PSI)

|

45,000

|

45,000

|

Recommended Products