-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

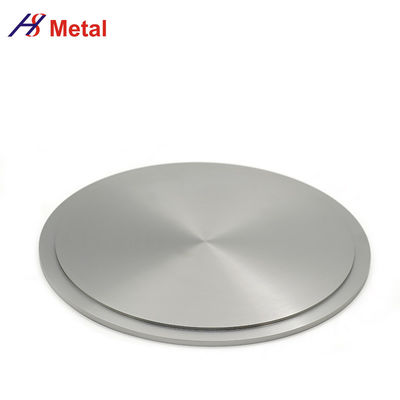

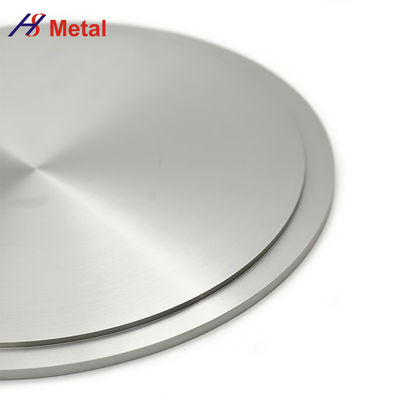

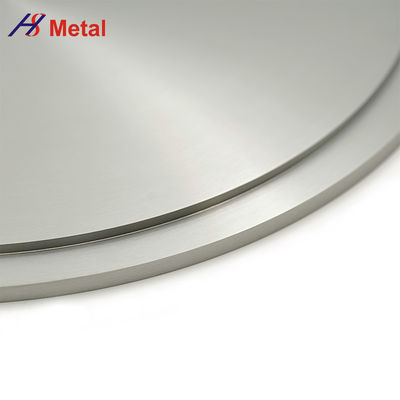

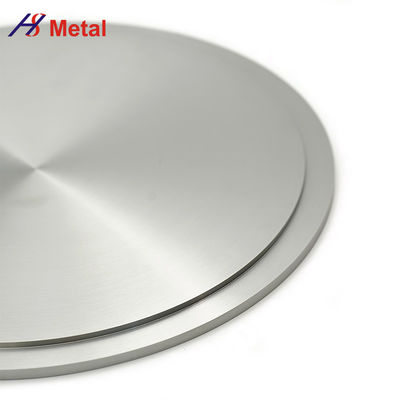

Molybdenum Disc Factory Moly Disc Vacuum Coating Molybdenum Sputtering Target High Temperature Resistance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mo Purity | 99.95% | Grades | Mo1 /Mo2 |

|---|---|---|---|

| Material Grade | Mo-1, Mo-2, TZM | Material | Molybdenum |

| Boiling Point | 4,639°C | Composition | Mo-±0.08% Zr, ±0.5% Ti, ±0.03% C |

| Elongation | <21% | Diameter | 10~100mm |

| Highlight | High temperature molybdenum Disc,sputtering target molybdenum Disc,vacuum coating molybdenum Disc |

||

1,Description:

-

Material: Molybdenum Sputtering Targets are made of molybdenum, a refractory metal known for its high melting point, excellent thermal and electrical conductivity, and resistance to corrosion. Molybdenum is widely used in sputtering applications.

-

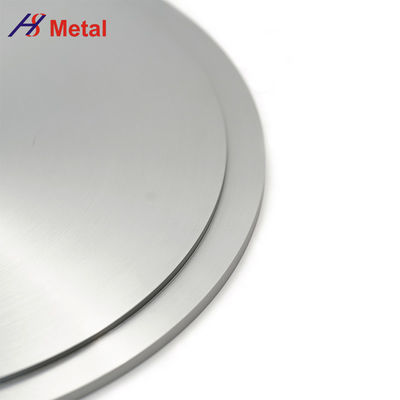

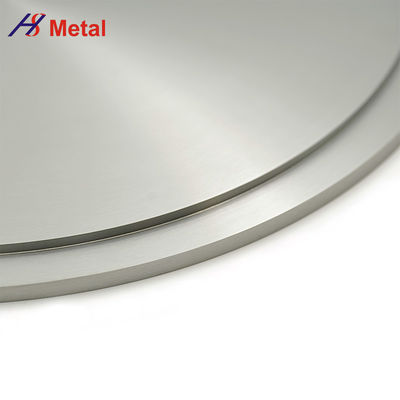

Shape and Structure: Molybdenum Sputtering Targets are typically disc-shaped or rectangular in form. They have a flat and uniform surface, ensuring consistent sputtering performance. The targets may be solid or bonded to a backing plate for added support.

-

High Purity: Molybdenum Sputtering Targets are available in high-purity grades, ensuring minimal impurities that could affect the quality of thin films. High purity is crucial for applications in semiconductor manufacturing, optical coatings, and thin film research.

-

Sputtering Performance: Molybdenum Sputtering Targets exhibit excellent sputtering performance, allowing for the deposition of high-quality thin films. They provide good sputtering efficiency, uniform erosion, and high deposition rates, resulting in precise and consistent film thickness.

-

Thermal and Electrical Conductivity: Molybdenum Sputtering Targets have high thermal and electrical conductivity, facilitating efficient heat dissipation during the sputtering process. This helps maintain target integrity and ensures stable sputtering performance.

-

Corrosion Resistance: Molybdenum Sputtering Targets possess good resistance to corrosion, making them suitable for use in various sputtering environments and processes. They can withstand the reactive gases and plasma conditions encountered during sputtering.

2,Specifications:

| Physical Property | Description |

|---|---|

| Material | Molybdenum |

| Purity | High purity grades available |

| Shape | Disc-shaped or rectangular |

| Melting Point | 2,623°C (4,753°F) |

| Density | 10.2 - 10.3 g/cm³ |

| Thermal Conductivity | 138 - 142 W/m·K |

| Electrical Conductivity | 25 - 30% IACS (International Annealed Copper Standard) |

| Corrosion Resistance | Good resistance to corrosion |

![]()