-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

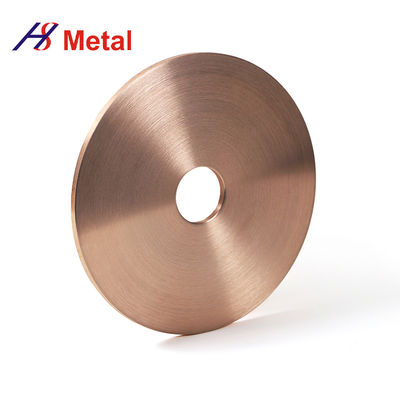

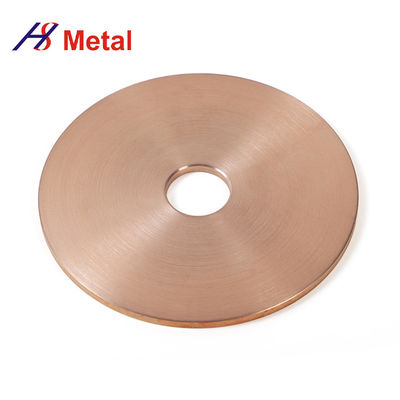

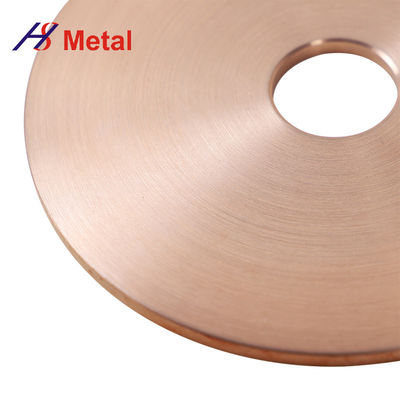

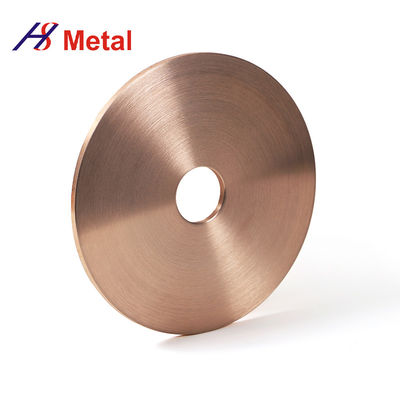

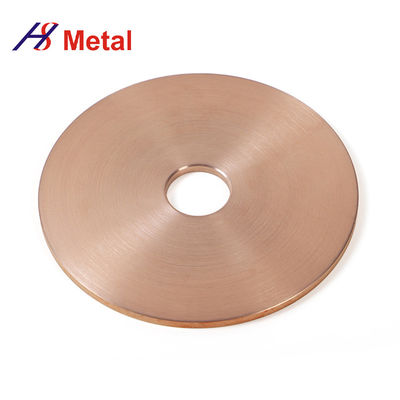

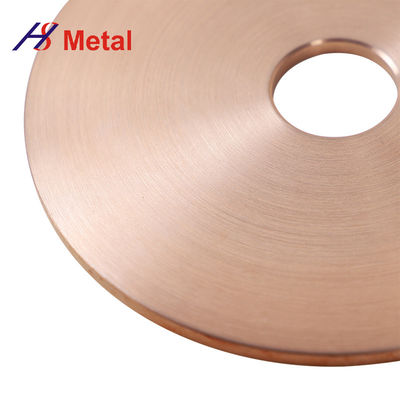

Corrosion Resistance Tungsten Copper Alloy Parts Tungsten Copper Alloy Disc

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Alloy | WCu | Electricalresistivity | 0.22 μΩ·m |

|---|---|---|---|

| Fracturetoughness | 2.5 MPa·m1/2 | Impact Toughness | ≥2.5J/cm2 |

| Impactstrength | 20 J/cm2 | Melting Point | 2700-2900°C |

| Thermalconductivity | 90 W/m·K | Yield Strength | 500-800 MPa |

| Highlight | corrosion resistance tungsten copper alloy,tungsten copper alloy parts,tungsten copper alloy disc |

||

1,Description:

-

Tungsten copper alloy parts combine the high strength and hardness of tungsten with the excellent thermal and electrical conductivity of copper.

-

These parts exhibit a unique combination of properties, making them ideal for applications requiring high strength, good thermal management, and electrical conductivity.

-

Tungsten copper alloy parts are commonly used in aerospace, defense, electronics, and high-performance engineering applications.

-

With their high melting point and resistance to thermal fatigue, these parts can withstand extreme temperatures and harsh operating conditions.

-

Tungsten copper alloy parts are often utilized in electrical and electronic devices, such as heat sinks, circuit breakers, electrodes, and contact materials.

-

The high density of tungsten in the alloy provides excellent radiation shielding properties, making these parts suitable for use in nuclear and radiation-related applications.

2,Specifications:

| Physical Property | Value |

|---|---|

| Density | Dependent on the tungsten-copper ratio, typically between 14-16 g/cm³ |

| Melting Point | Approximately 3,400°C |

| Thermal Expansion Coefficient | 4.5 - 6.5 x 10^-6 /°C (in the room temperature to 300°C range) |

| Thermal Conductivity | 150 - 200 W/m·K (at room temperature) |

| Electrical Conductivity | 20 - 60% IACS (International Annealed Copper Standard) |

| Hardness | Dependent on the tungsten-copper ratio, typically between 200-350 HB |

![]()