-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

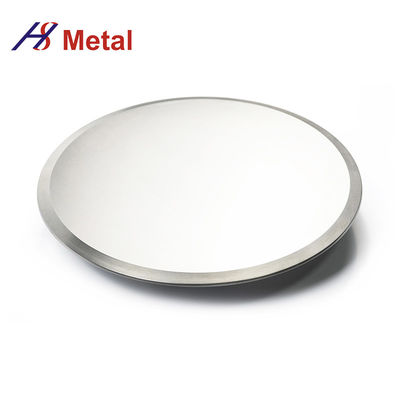

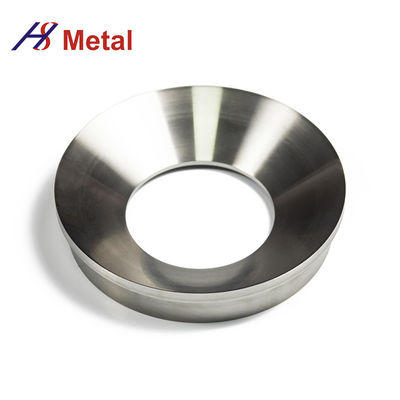

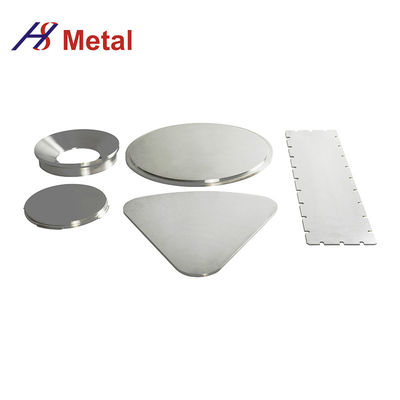

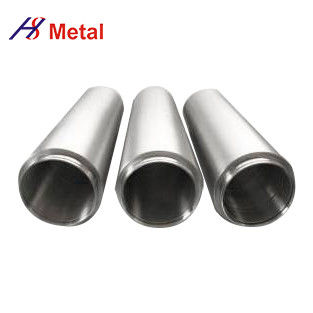

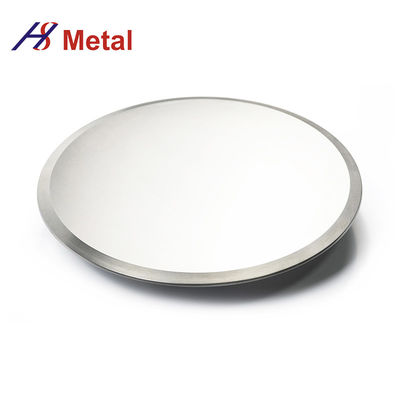

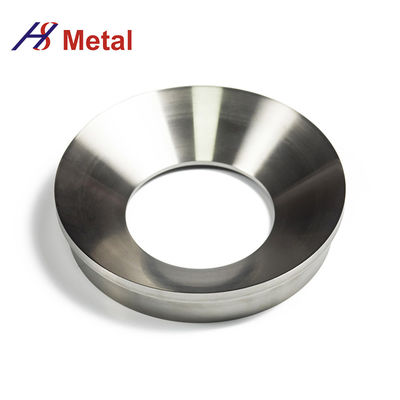

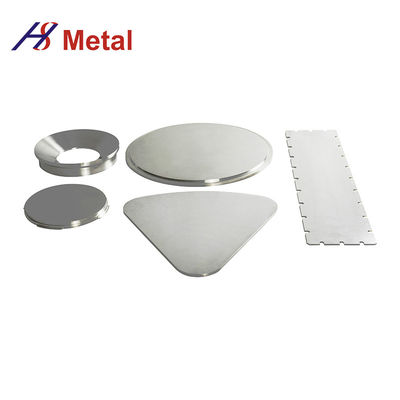

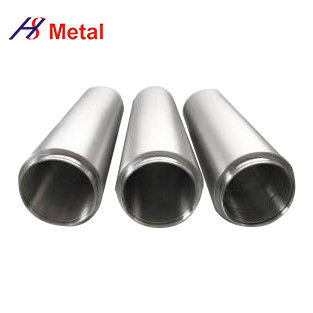

Molybdenum Sputter Targets Sheet Round Square Triangular Sheet Pure Molybdenum Tube

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Atomic Weight | 95.94 | Diameter | 10~100mm |

|---|---|---|---|

| Hs Code | 81019500 | Melt Point | 2620 °C |

| Mo Purity | 99.95% | Product Standard | ASTM B386, GB/T3876 |

| Working Temperature | 700~1400C | Young'S Modulus | 329 GPa |

| High Light | round molybdenum sputtering target,pure molybdenum sputtering target,round molybdenum sputtering |

||

1,Description:

Material: Molybdenum sputter targets are made from pure molybdenum (Mo) metal.

Density: Molybdenum has a high density, typically ranging from 10.2 to 10.3 grams per cubic centimeter (g/cm³).

Melting Point: Molybdenum has a very high melting point of approximately 2,623 degrees Celsius (4,753 degrees Fahrenheit), which allows it to withstand high-temperature sputtering processes.

Thermal Conductivity: Molybdenum exhibits good thermal conductivity, facilitating efficient heat dissipation during sputtering.

Electrical Conductivity: Molybdenum is a relatively poor electrical conductor compared to materials like copper or aluminum.

2,Specifications:

| Property | Description |

|---|---|

| Material | Pure Molybdenum (Mo) |

| Density (g/cm³) | 10.2 to 10.3 |

| Melting Point (°C) | Approximately 2,623 |

| Thermal Conductivity (W/m·K) | 138 to 142 |

| Electrical Conductivity | Relatively poor electrical conductivity |

| Purity | Typically 99.95% to 99.99% or higher |

| Grain Structure | Fine-grained structure |

| Corrosion Resistance | Excellent resistance to corrosion and oxidation |

| Coefficient of Thermal Expansion (CTE) (ppm/°C) | 4.8 to 5.3 |

![]()