-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

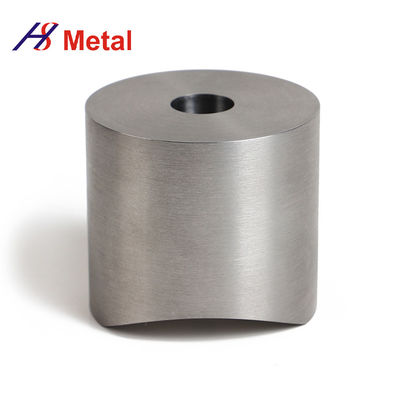

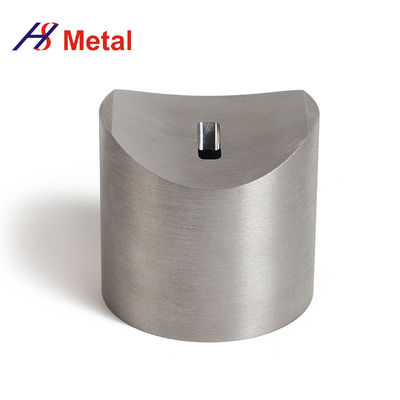

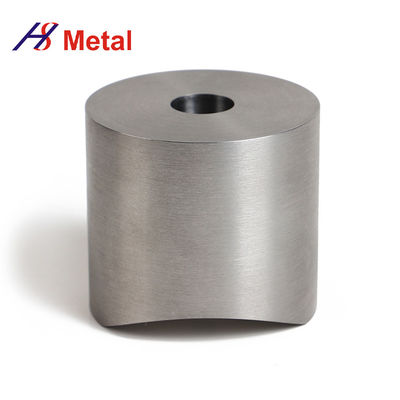

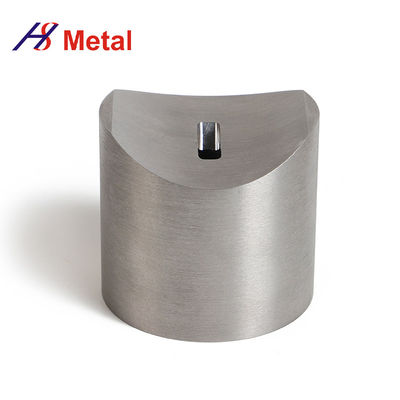

Customized Tungsten Heavy Alloy Radiation Shield Part

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| MOQ | 1 Piece | Material | Tungsten |

|---|---|---|---|

| Packaging | Wooden Case, Carton, Pallet, Etc. | Processing | Turning, Milling, Drilling, Grinding, Etc. |

| Size | Customized | Surface | Polished/Ground |

| Surface Treatment | Sandblasting, Painting, Anodizing, Etc. | Tolerance | ±0.01mm |

| Density | 18.5-19.1 G/cm3 | Electrical Resistivity | ≤0.02 Ω·m |

| Elongation | ≥10% | Fracture Toughness | ≥6 MPa·m1/2 |

| Impact Strength | ≥25 J/cm2 | Magnetic Permeability | ≤1.05 |

| Specific Heat | ≥0.12 J/g·K | Thermal Conductivity | ≥60 W/m·K |

| Highlight | customized tungsten heavy alloy,radiation shield part tungsten heavy alloy |

||

1,Description:

Material: Tungsten heavy alloys are composite materials that consist primarily of tungsten along with small additions of other metals such as nickel, iron, or copper.

High Density: Tungsten heavy alloys have an exceptionally high density, typically ranging from 17 to 19.3 grams per cubic centimeter (g/cm³), which is among the highest of all metallic materials.

High Melting Point: Tungsten heavy alloys have a high melting point of approximately 3,400 degrees Celsius (6,152 degrees Fahrenheit), allowing them to withstand extreme temperatures without melting or deforming.

2,Specifications:

| Density | 17 - 19.3 grams per cubic centimeter (g/cm³) |

| Melting Point | Approximately 3,400 degrees Celsius (6,152 degrees Fahrenheit) |

| Mechanical Strength | Excellent strength and hardness, resistant to deformation |

| Ductility | Exhibits good ductility, suitable for forming processes |

| Elastic Modulus | High elastic modulus for stiffness and dimensional stability |

| Thermal Conductivity | Relatively low thermal conductivity, suitable for insulation |

![]()