-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

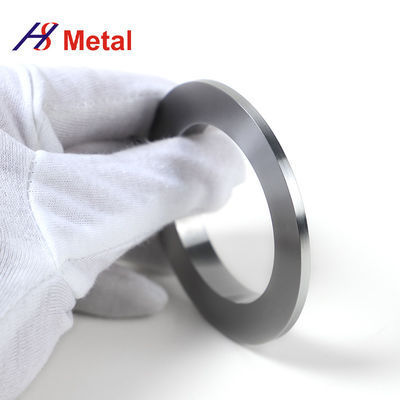

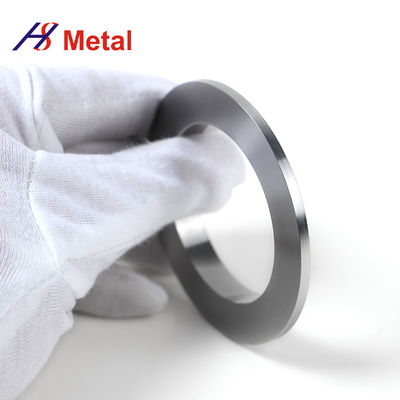

99.95% Molybdenum Products Rings High Melting Point Customized Size

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Molybdenum Products Rings | Density | ≥10.2g/cc |

|---|---|---|---|

| Melting Point | 2610ºC | Purity | 99.95% |

| Advantage | High Melting Point | Size | Customized |

| High Light | High Melting Point Molybdenum Products,High Melting Point Molybdenum Rings,Customized Molybdenum Rings |

||

99.95% Molybdenum Products Rings High Melting Point

Molybdenum Products Rings Quick Details

1) high melting point, high strength,

2) smooth and clean surface,

3) good conductions, small linear expansion coefficient and good heat-resistance

Chemical requirements

|

Element |

Ni |

Mg |

Fe |

Pb |

Al |

Bi |

Si |

Cd |

Ca |

P |

|

Concentration(%) |

0.003 |

0.002 |

0.005 |

0.0001 |

0.002 |

0.0001 |

0.002 |

0.0001 |

0.002 |

0.001 |

|

Element |

C |

O |

N |

Sb |

Sn |

Mo |

|

|

|

|

|

Concentration(%) |

0.01 |

0.003 |

0.003 |

0.0005 |

0.0001 |

balance |

|

|

|

|

Parameters

|

Atomic number |

42 |

|

CAS number |

7439-98-7 |

|

Atomic mass |

95.94 [g/mol] |

|

Melting point |

2620 °C |

|

Boiling point |

4639 °C |

|

Density at 20 °C |

10.22 [g/cm] |

|

Crystal structure |

Body-centered cubic |

|

Coefficient of linear thermal expansion at 20 °C |

5.210-6 [m/(mK)] |

|

Thermal conductivity at 20 °C |

142 [W/(mK)] |

|

Specific heat at 20 °C |

0.25 [J/(gK)] |

|

Electrical conductivity at 20 °C |

17.9106 [S/m] |

|

Specific electrical resistance at 20 °C |

0.056 [(mm2)/m] |

Applications

Molybdenum Products Rings are widely used ed in national defense and the story, the electronic industry, aeronautics & Astron, aquatics, and mechanical engineering. The paraircraft’s wings and the screening materials mold mold commonly use molybdenum.

Usage

Support wire, lead-in wire, printer needle, various electrodes and quartz furnaces, filament, high-speed tools, auto products,

sputtering targets