-

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future.

John WilsonHypersolid Metal Tech Co., Ltd is a very responsible company that can effectively solve our problems. I hope there will be opportunities to work together in the future. -

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

miaThis company is the best I have ever seen. The company's employees are particularly enthusiastic and able to respond and meet our needs. If there is a need in the future, I will still work with you!

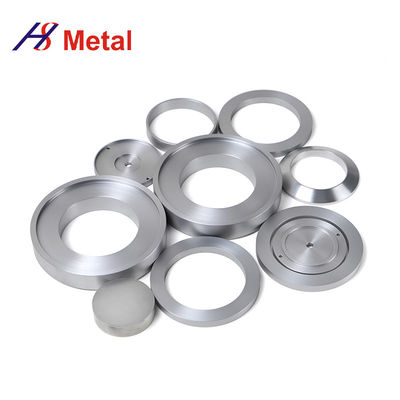

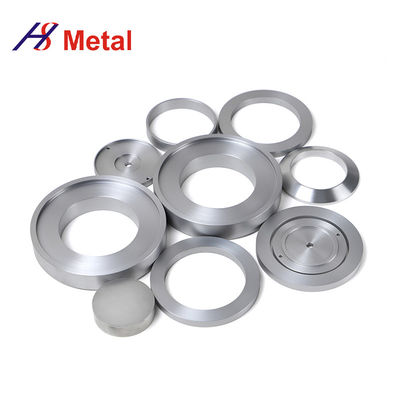

99.95% Min Molybdenum Ring High Temperature Resistance For Industry Customized

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Molybdenum Ring | Density | ≥10.2g/cc |

|---|---|---|---|

| Melting Point | 2610ºC | Application | Electronic Industry, Aeronautics & Astron, Aquatics, |

| Advantage | High Temperature Resistance | Size | Customized |

| Highlight | Industry Molybdenum Ring,Molybdenum Ring Customized |

||

99.95%Min Molybdenum Ring High Temperature Resistance

Quick Details

Material: pure molybdenum 99.95%Min

Density10.2g/cc

Melting point: 2610C

Chemical requirements

|

Element |

Ni |

Mg |

Fe |

Pb |

Al |

Bi |

Si |

Cd |

Ca |

P |

|

Concentration(%) |

0.003 |

0.002 |

0.005 |

0.0001 |

0.002 |

0.0001 |

0.002 |

0.0001 |

0.002 |

0.001 |

|

Element |

C |

O |

N |

Sb |

Sn |

Mo |

|

|

|

|

|

Concentration(%) |

0.01 |

0.003 |

0.003 |

0.0005 |

0.0001 |

balance |

|

|

|

|

Parameters

|

Atomic number |

42 |

|

CAS number |

7439-98-7 |

|

Atomic mass |

95.94 [g/mol] |

|

Melting point |

2620 °C |

|

Boiling point |

4639 °C |

|

Density at 20 °C |

10.22 [g/cm] |

|

Crystal structure |

Body-centered cubic |

|

Coefficient of linear thermal expansion at 20 °C |

5.210-6 [m/(mK)] |

|

Thermal conductivity at 20 °C |

142 [W/(mK)] |

|

Specific heat at 20 °C |

0.25 [J/(gK)] |

|

Electrical conductivity at 20 °C |

17.9106 [S/m] |

|

Specific electrical resistance at 20 °C |

0.056 [(mm2)/m] |

Applications

Molybdenum rings are widely used ed in national defense and the story, the electronic industry, aeronautics & Astron, aquatics, and mechanical engineering. The paraircraft’s wings and the screening materials mold mold commonly use molybdenum.

Usage

Support wire, lead-in wire, printer needle, various electrodes and quartz furnaces, filament, high-speed tools, auto products,

sputtering targets